If you’re in the maize milling industry, chances are that you’ve read about or implemented a preventive maintenance program to ensure the efficiency of your maize mill. But how frequently do YOU review and measure the efficiency of your program?

WHAT IS PREVENTATIVE MAINTENANCE?

Preventive maintenance refers to all maintenance done in order to prevent milling equipment failure, or to spot a failure early. Preventive maintenance practices include the inspection, lubrication and cleaning of your equipment and production areas.

A sound preventative maintenance program is the foundation for equipment reliability, and is directly proportional to the maize milling facility’s processing and financial performance.

A good preventive maintenance program requires planning, tracking and accounting of the time and cost of all maintenance-related activities. In the competitive grain processing business, a miller must be more cost-effective than the competitor to succeed. An effective preventive maintenance program can help your maize milling business to maintain its competitive advantage by reducing maintenance costs and increasing available production time for the processing plant.

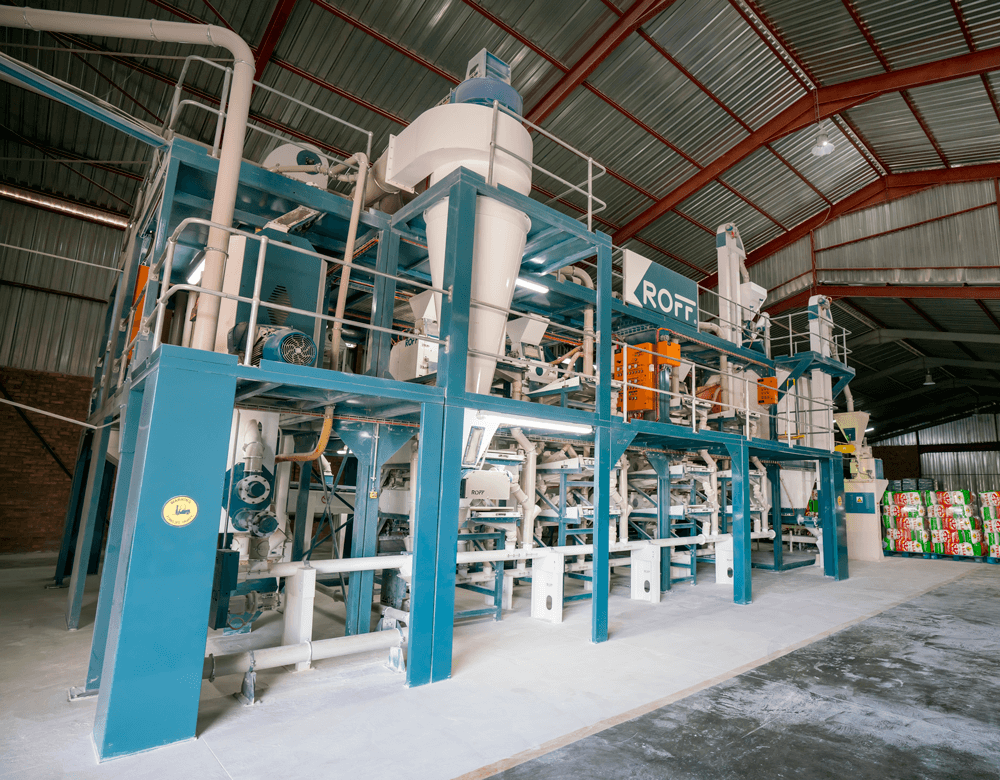

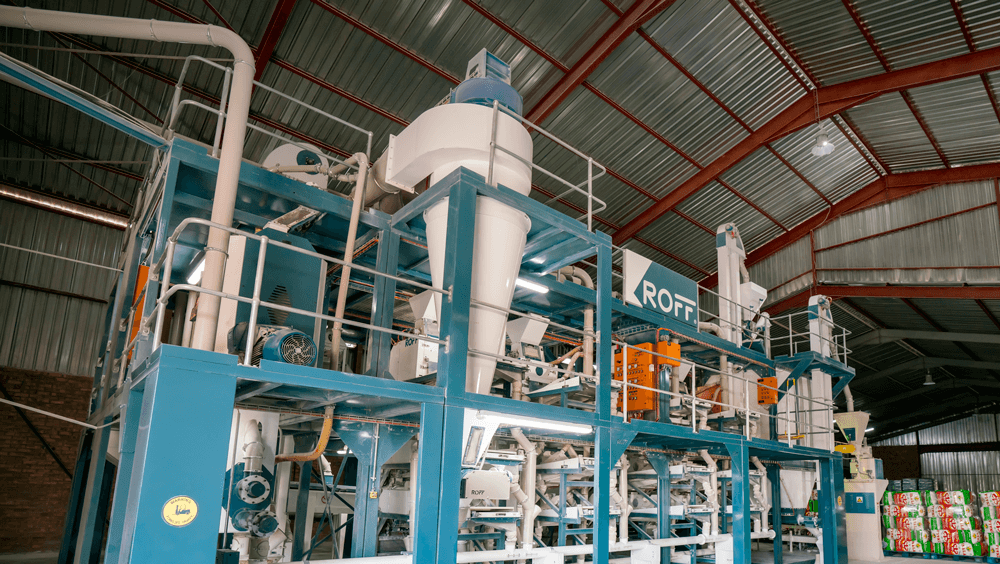

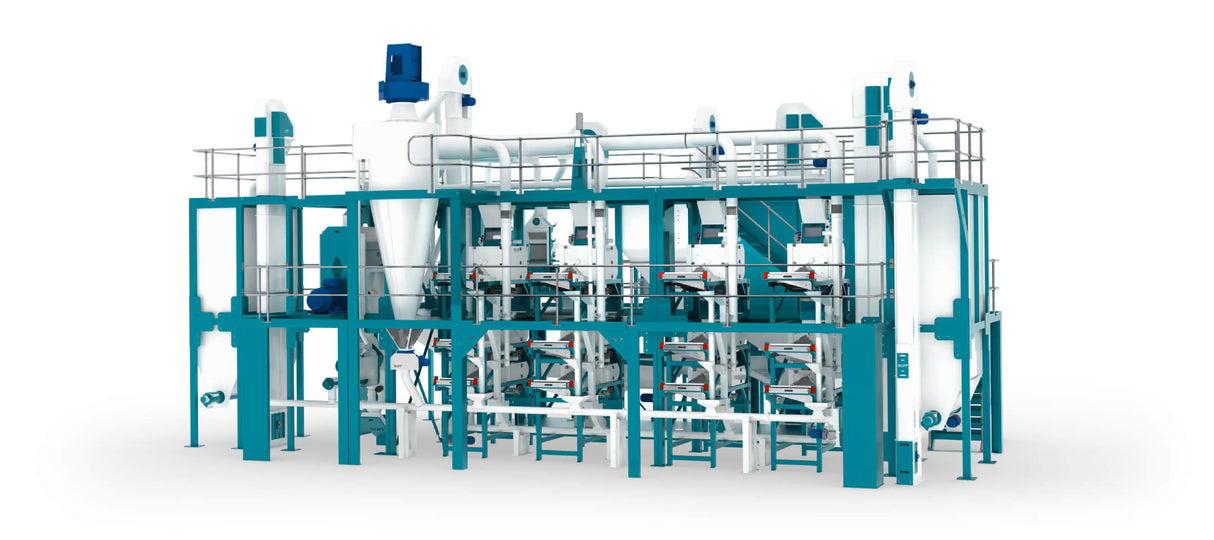

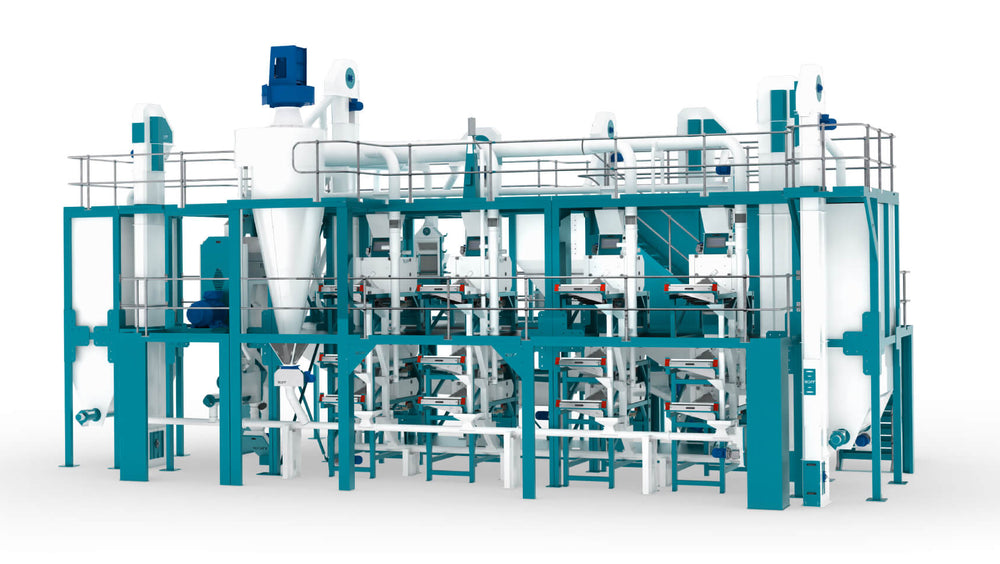

Using Roff Genuine Parts and certified technical teams to maintain your plant extends the life of your equipment. It also gives you a competitive advantage by decreasing your downtime and keeping your extraction rates as high as possible. Let’s help you get the most out of your Roff Milling equipment.

Why review preventative maintenance practices?

Periodic evaluation of preventative maintenance practices can lead to:

- Increased mill productivity

- Reduced maintenance costs

- Increased profitability.

Set your goals and benchmarks

To determine the effectiveness of a preventive maintenance program, you must first decide on the goals and objectives for the program. Benchmarking against current maintenance practices within the milling facility is a good starting point. Targeting a goal established by the industry or other facilities within the company is an objective standard which can measure improvement as well.

Areas that are easy targets to measure and improve:

- Labour cost (both in-house and contracted)

- Spare part inventory

- Planned and unplanned downtime for the processing facility.

For example: An easily measured goal is tracking the number of hours or occurrences that cause production interruptions. Excessive unplanned repairs should lead to a review of the facility’s approach to preventative maintenance.

Define roles and responsibilities

When reviewing maintenance practices, it’s incredibly important to address the existing roles and responsibilities of the various departments in the milling operation that conduct maintenance activities.

Ask these questions:

- Are maintenance tasks conducted by personnel on multiple shifts?

- How are responsibilities divided?

- Do the day-shift personnel handle maintenance issues within day-shift hours, and which maintenance personnel are responsible for issues that occur during other hours?

- Who has primary responsibility for preventive maintenance tasks?

- What maintenance is performed by other departments, such as cleaning assignments for sifters and roll changing, that is often done by the milling department?

- Do preventive maintenance tasks receive the priority necessary to stay on schedule?

Answering these questions is only the beginning in your task of reviewing the effectiveness of how the preventive maintenance program is implemented.

SCHEDULING AND PLANNING

All effective preventive maintenance programs begin with scheduling. You should assign sufficient time or people for the specific task of completing scheduled preventive maintenance:

- Are there a significant number of work orders that were unplanned? When a repair is required due to an emergency or unplanned occurrence, everyone’s productivity suffers. Work orders need to be well planned and the required materials ready for the mechanics when they received their assignments. When preventive maintenance receives priority, unplanned downtime will be reduced.

- Tracking of repairs is important. Is the same piece of equipment being repaired often? Are repeated repairs tracked to ensure the cause of the breakdown is eliminated, or is it simply the symptom? If a fan bearing is replaced, is it confirmed the fan is properly balanced and the belts are properly tensioned? If a motor burns up, are the fuses checked or overloaded to see why they failed to protect the motor?

- Regularly scheduled infrared scanning of electrical circuits and panels identify hot spots. Hot spots in motor control circuits are the result of loose or worn connections. Infrared scanning identifies these potential problems before they cause unplanned downtime.

- Vibration analysis of motors and all rotating equipment helps with the early detection of wear to allow for corrective actions. Vibration is the most destructive force in any rotating equipment. Wear on bearings, belts, isolation pads and many other parts can lead to vibrations in equipment that are not easily noticed. By monitoring equipment for vibrations, they can be identified and corrected before the vibrations result in excessive wear on the equipment.

Monitoring equipment is vital for proper scheduling and planning. There are many ways to monitor periodic maintenance requirements for equipment. Here are some:

- Fixed interval maintenance is required for almost all equipment. The best resource to determine the necessary interval is the manufacturer. Changing the oil and air filters in positive displacement blowers, and tightening the brackets suspending a sifter, are examples of maintenance that should be performed on a regular fixed interval, generally based on the number of hours a piece of equipment is operated.

- Objective interval maintenance is based on monitoring operating conditions of equipment and planning maintenance based on pre-determined targets. One example in grain processing facilities is the monitoring of Magnehelic gauges measuring the pressure drop across filter socks to determine when to replace or clean the socks. Another example is the monitoring of amp loads and product granulation to determine when to replace worn grinding rolls.

- Subjective inspections are the responsibility of all plant personnel. Subjective inspections are as simple as using one’s senses when walking through the facility. Stop, look, listen, feel and smell. Be aware of changes in the mill environment that may be caused by equipment wear.

MONITORING THE SPARES AND INVENTORY

An evaluation storeroom inventory can be a valuable experience, and the chance to ensure significant cost savings. Identifying wrong or out-dated parts and getting them out of inventory ultimately saves time and space.

It may also result in unexpected revenue if they can be sold and used by another maize mill within your company or region. Time and money can be lost if the storeroom issues the incorrect parts for a work order. Supplies such as lubricants need to be removed if they are not useable in existing equipment. Equipment failure or product contamination may be the result of using the wrong lubricant. Just like every other facet of maintenance, getting the process implemented to purchase and store necessary spares under control requires good planning and scheduling.

MEASURING MAINTENANCE PERFORMANCE

-

Cost: A common measurement of maintenance performance is the cost. Maintenance costs are often used to compare maintenance performance between companies or between mills within the same company. However, setting a standard for measuring maintenance costs is difficult. Each company (sometimes even mills within the same company) may have their own definition of maintenance costs.

That’s why maintenance cost comparisons should always be accompanied by a clear definition of what’s included and excluded for each plant. Some examples of maintenance costs that may or may not be included are: the cost of capital investment or scheduled equipment replacement, training, and maintenance tasks performed by employees in other departments.

- Time is another common measure to track maintenance performance. E.g. the time it takes to perform common maintenance tasks such as sifter maintenance or roll replacements. Lost time due to breakdowns or unplanned production interruptions is also an important measure of maintenance effectiveness. Unplanned production interruptions can be expensive as production is lost, but you are also paying employees for the lost time. Tracking of lost time due to unplanned equipment failures should be a vital part of evaluating the effectiveness of maintenance practices.

IMPLEMENTING THE PLAN

A large initiative, such as measuring the effectiveness of or implementing a preventive maintenance program, takes a lot of commitment. Top management, team leaders and team members must be committed to the process.

What are some of the most common causes for not meeting the long-term objectives of a preventive maintenance program?

- Management does not understand the resources and long-term support required to implement the program;

- Program initiatives and goals that are short-sighted and too cost-focused instead of long-term and reliability-focused;

- Conflicted organisational goals and objectives;

- Not understanding that the reliability and maintenance improvement initiative is a continuous process driven by disciplined thoughts and actions of people, not a program with a defined beginning and end; and

- Technology applied and implemented that’s secondary to the behaviour of the employees charged with its implementation and usage.

OVERCOMING THE CHALLENGES

A lack of communication is often the greatest challenge when implementing a new process or evaluating an existing program. A clear message of teamwork and the desire to improve is crucial, without creating an atmosphere of distrust and assigning blame for past mistakes.

Preventive maintenance programs require a high level of commitment and regular evaluation of their effectiveness. However, a well-managed, fully implemented preventive maintenance program will reward the miller with greater profitability, improved process efficiencies and better employee satisfaction due to a job well done.

Source:

World-Grain.com, Best practices equal profits

3 comments

ROFF has been always the best. Thank you for the advice

———

Roff Milling replied:

Hello Tendai,

Thank you, we strive to only give the best services to our clients.

Thanking you for keeping us updated and teaching the way we should maintain our our equipment. It’s 20 years of reliable service I’m getting from my two ROFF Mark 1 grinding mill machines.

———

Roff Milling replied:

Hello Modest, thank you for this great feedback., we strive to only serve our clients the best we can.

Thanking you for keeping us updated and teaching the way we should maintain our our equipment. It’s 20 years of reliable service I’m getting from my two ROFF Mark 1 grinding mill machines.

———

Roff Milling replied:

Hello Modest, thank you for this great feedback., we strive to only serve our clients the best we can.