BULK GOODS HANDLING, DUST-EXTRACTION AND VENTILATION

Jacob modular pipework systems

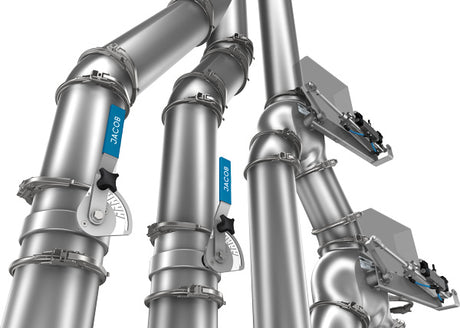

The modular system developed by JACOB features over 8 000 standard articles alone and combines versatile options for custom designs with simple assembly. Distributed by Roff Industries, JACOB pipework systems offer tailored results for any challenge.

-

Dust Extraction & Exhaust Air

Keep your mill clean, compliant and efficient. Jacob ducting is widely used for aspiration at cleaners, roller mills and plansifters, and for central housekeeping lines—controlling airborne dust and protecting product quality and people.

Why it works in milling

- Modular capture to fan – From pick-up points to manifolds and filtration, the system scales with your plant and is easy to balance with throttles/actuators.

- Food-compliant options – Stainless and coated components for aspirating exhaust air in food environments.

- Proven in flour mills – Installed in major flour operations for dust extraction and safe exhaust routing.

Typical extraction points

- Intake pit & cleaners (coarse dust), roller stands (fines), sifters, bagging lines, and general housekeeping trunks to the bag filter.

Build your system with parts stocked by Roff

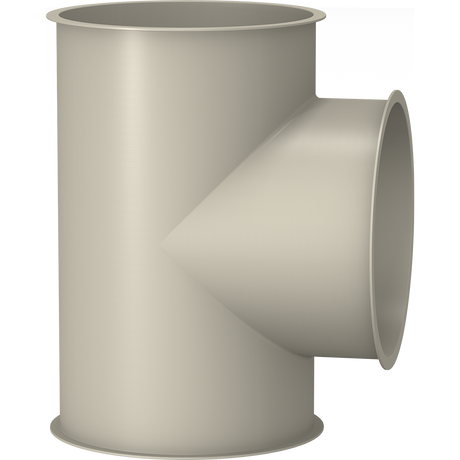

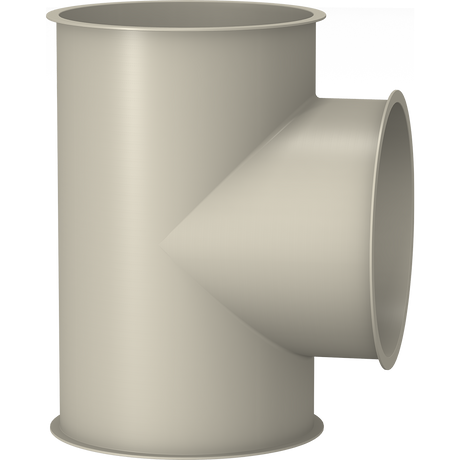

- Straight pipe & bends for mains and branches.

- Transitions & spouts to pick-up hoods and machines.

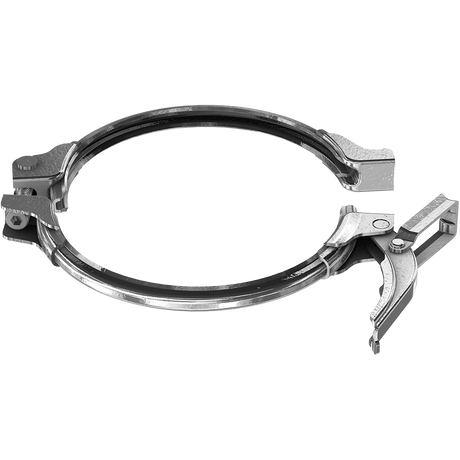

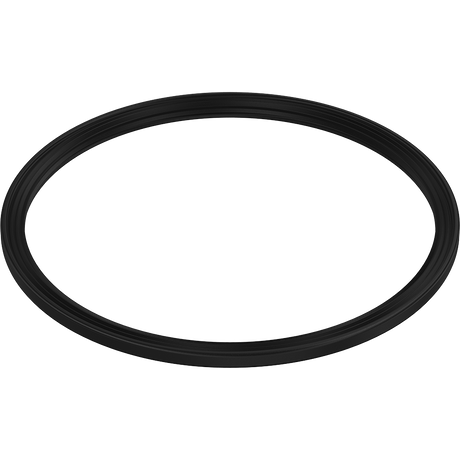

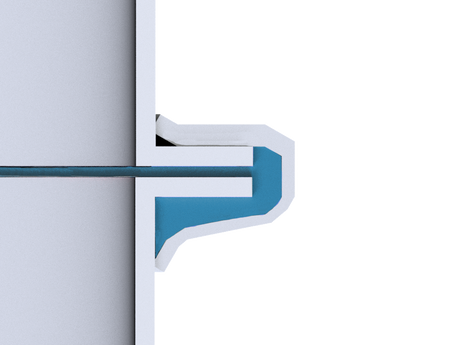

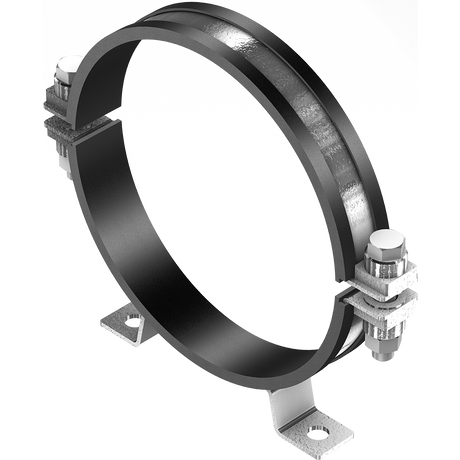

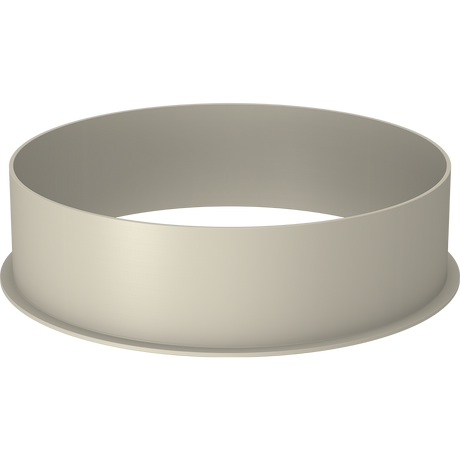

- Pull-rings + U-seals for air-tight, quick assembly; compatible with Quick-Connect.

Shop Jacob ducting & spouting for the full modular range.

-

Bulk Material Handling

Move grain, maize meal and flour reliably with modular spouting built for mills. Jacob’s lipped, pull-ring system lets you configure, expand and maintain your plant faster—so you keep meal flowing and downtime low. The system is proven in flour mills for gravity and low-pressure product transfer, with options for food-contact, wear protection and explosion-risk areas.

Why it works in milling

- Fast, tight, flexible joints – Lipped ends + U-seals + pull-rings deliver leak-tight connections you can assemble and reconfigure quickly during shutdowns.

- Built for grain, maize meal & flour – Components and finishes suited to cereals, seeds and feed, including stainless options for hygiene-critical routes.

- Safety & wear options – Conductive wear protection and explosion-risk design practices already deployed in large European and African maize meal and flour mills.

Typical routes in a mill

- Silo discharge → cleaning → conditioning → degerm/roller floor → packing. Jacob straight pipes, 45° spouts, transitions and inspection pieces cover each leg, with long-radius elbows for gentle product handling.

Build your route with Roff stock items

- Push-in pipes – leak-proof to 0.5 bar with Jacob U-seals and pull-rings (ideal for short pressure assists).

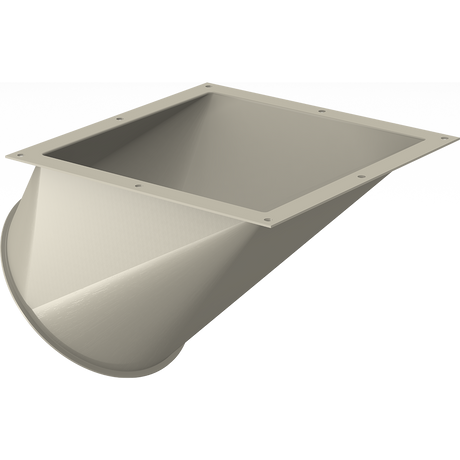

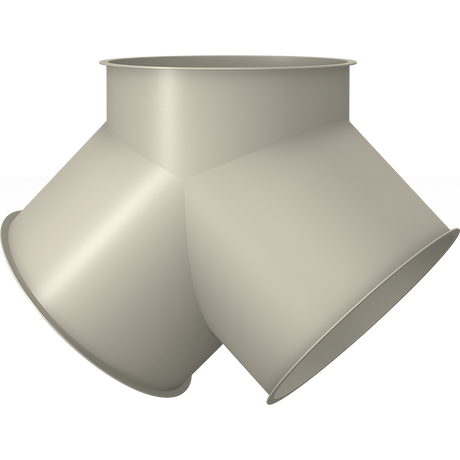

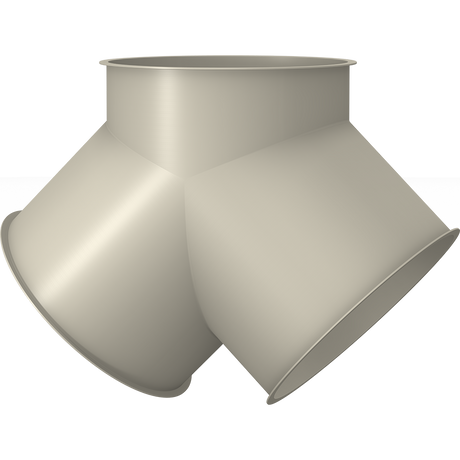

- 45° spouts – smooth gravity changes with minimal impact.

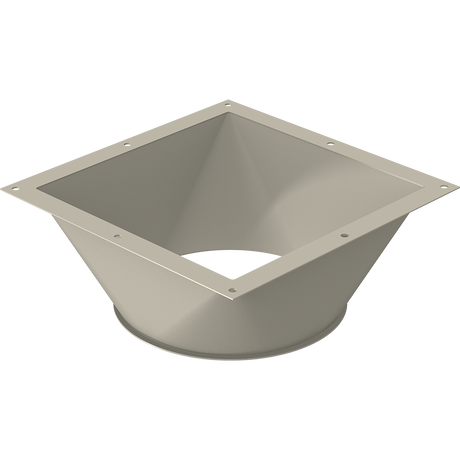

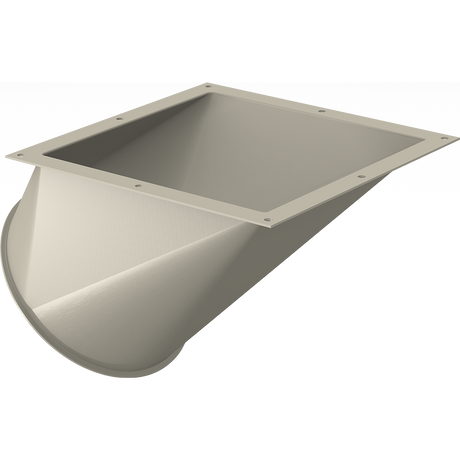

- Square-to-round transitions – mate chutes, hoppers and machine outlets to round duct.

-

Low pressure conveying

Product and air conveying - JACOB pipework systems can also be used to convey and extract products in low-pressure applications.

- Conveyor lines or extraction, for example of polystyrene, tobacco, wood shavings, plastics as powder or granulate, as well as plastic or electronic waste in recycling facilities

- Air conveying for air-conditioning, cooling and exhaustAir conveying for air-conditioning, cooling and exhaust

When you need gentle, compact and hygienic product transfer—e.g., finished flour or maize meal to packing or bran to storage—Jacob tubing excels in low-pressure pneumatic conveying. The system supports steel and stainless routes, long runs and easy re-routing as your plant grows.

Why it works in milling

- Optimised for low-pressure air/product conveying – Wide component set tailored for dilute-phase routes at modest pressures.

- Clean, flexible layouts – Air conveying saves floor space versus mechanical conveyors; earthing continuity and smooth bores support product flow and static control. (Industrial case experience).

- Food-grade options – Materials and finishes for flour contact and easy sanitation.

Typical routes in a mill

- StorageFlour bins → packing lines; bran off-take → silo; refeed lines to blending.

Build your route with stocked parts (Roff)

- Push-in pipes for pressure sections up to 0.5 bar.

- Smooth spouts & elbows for low loss and gentle handling.

- Transitions to connect blowers, cyclones/filters and packing machines.

- See Jacob ducting & spouting for more components and sizes in stock.

The Jacob collection

View all

More about JACOB products

- Modular pipework system with over 8 000 standard parts

- Welded, lipped pipes and moulded components

- Steel: powder-coated, galvanised or stainless

- 60 - 1600mm diameter in the standard range

- 1 to 3 mm wall thickness

- Connection: pull ring, loose flange or welded-on flange

- Shock-explosion proof piping available

- FOOD GRADE line

- DETECTABLE DESIGN line

- Up to 400mm diameter usually available directly from stock

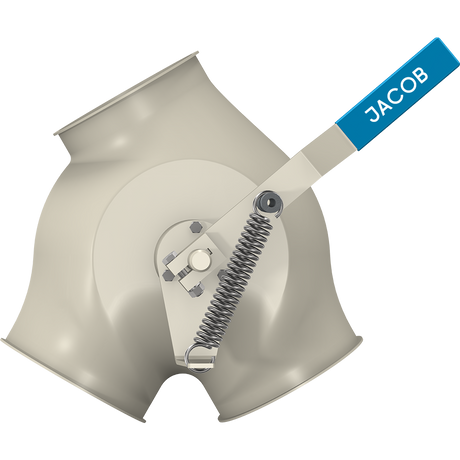

Pull-ring system from JACOB

Modular pipework systems from JACOB