Roff Milling Expands: New Zambia Branch Enhances Sub-Saharan Services

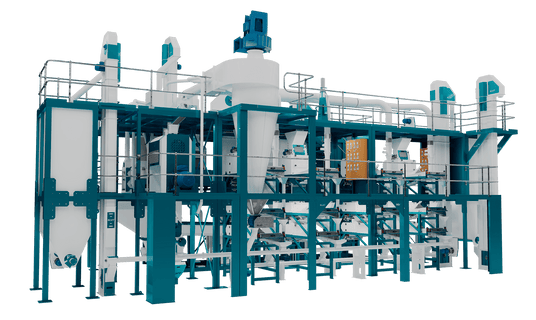

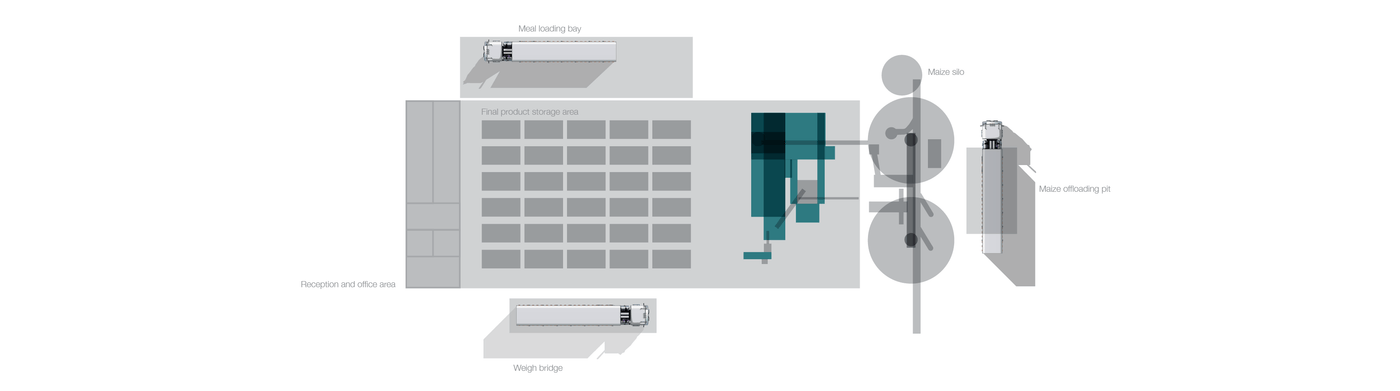

Roff Milling Zambia opened its doors on 13 March 2025! This new Roff Milling branch located in Kitwe, Zambia, is set to connect our client base in sub-Saharan Africa with...

Jan Jordaan |