Introduction

Boost your profits by upgrading your community milling business to a more profitable commercial mill. Upgrading or expanding is an essential step for long-term growth. Transitioning your mill from a Posho or MK2S to a higher capacity SP-1 maize mill means you can produce higher-quality maize meal on a larger scale, resulting in more profit.

Understanding the Differences

Community milling involves charging a service fee to mill maize locally, while commercial milling produces packaged maize meal for broader distribution. Both aim for profitability, but they achieve it through distinctly different approaches.

|

Community milling |

Commercial milling |

|

Requires less capital to start |

Requires more funds, but is more profitable due to economies of scale |

|

Mill maize for the community and charge a fee for the service |

Mill and package maize meal sold locally or distributed to other areas |

|

Maize supply comes from the local area but is subject to seasonal availability. Optionally buy maize from other areas and sell it to the local community |

Maize supply from local farmers, regional areas, co-ops or from own farm |

|

Takes up less space |

Requires infrastructure such as a warehouse with a clean water supply |

|

Less power supply needed, 10kW @ 20Amps (380V) power |

Starting from 25kW @ 50Amps (380V) power supply needed |

Commercial milling involves more steps and equipment in the milling process, ensuring higher quality maize meal and a larger capacity output. This higher quality allows you to sell to a broader market, leading to increased profitability. On the other hand, community milling is a simpler process, serving local community needs; but it comes with limitations in capacity and efficiency. If your goal is to expand your business, upgrading from a Posho mill to the SP-1 maize mill, or adding an SP-1 mill is a logical step.

Main differences in setup

To illustrate how achievable an upgrade of an existing community milling setup is, let’s first take a look at the main differences between a Posho/MK2S and SP-1 Edge maize mill setup:

|

Community Mill |

Startup Commercial Mill |

|

|

Product |

Maize meal and bran |

Maize meal and bran |

|

Grade of product* |

Sifted or special maize meal |

Super / Grade 1 maize meal Special / Grade 2 maize meal |

|

Capacity/input |

750kg/hour - Posho roller mill 650kg/hr - MK2S roller mill |

650kg/hour to 1ton/hour |

|

Milling process: |

||

| Intake and cleaning |

Manual input by hand |

Intake screw conveyor C6 Pre-cleaner with aspiration |

| Maize conditioning |

Optional 70l batch mixer |

Surge bin (Optional) Conditioning conveyor |

| Degermination |

Not applicable |

520 Degerminator Surge bin |

| Milling and final product |

Posho roller mill or MK2S roller mill |

MK2S or MK6 Roller mill Final product bin |

*Estimated, depending on maize quality

You have two options on how to proceed, depending on how much you have available to invest to expand your business and the quality of maize meal your target market demands.

Upgrading your existing Posho or MK2S to an SP-1 is possible, but a MK-6 is recommended if your aim is to produce a higher quality product. Roff recommends the MK-6 roller mill as the foundation for your new commercial SP-1 maize mill.

To help you make an informed decision we will explore both scenarios.

What you need to supply:

| Posho or MK2S | SP-1 | |

|

Building / grain silos |

Small building such as a garage, see footprint |

Building able to accommodate the SP-1 (refer to footprint) and optional grain silos or maize bag storage area |

|

Water supply to conditioning |

Optional |

At least 20 liters of water per hour at 2 bar pressure |

|

Power requirement |

9.5 to 11kW |

DB Board with power supply to Roff-supplied Motor Control Centre Panel. The main supply ranges from 50 to 150Amp moulded breaker * |

|

Forklift |

Forklift for offloading |

Forklift for installation |

|

Extraction rates |

82 - 85% |

69 - 74% Super/Grade 1 maize meal 82 - 84% - Special / Grade 2 maize meal |

|

Footprint |

2.8m (h) x 2m (l) x 1m (w) |

5.5m (h) x 16.5m (l) x 8.5m (w) * |

|

Typical space required |

3m x 6m (Single Garage) |

10m x 20m * |

* Depending on model

Why is the SP-1 the logical next step for growth?

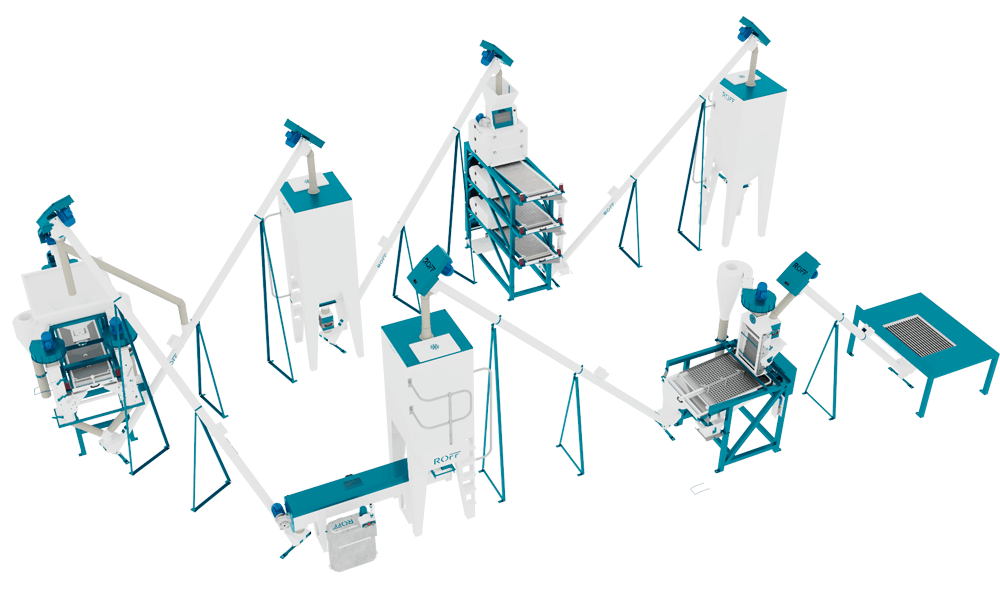

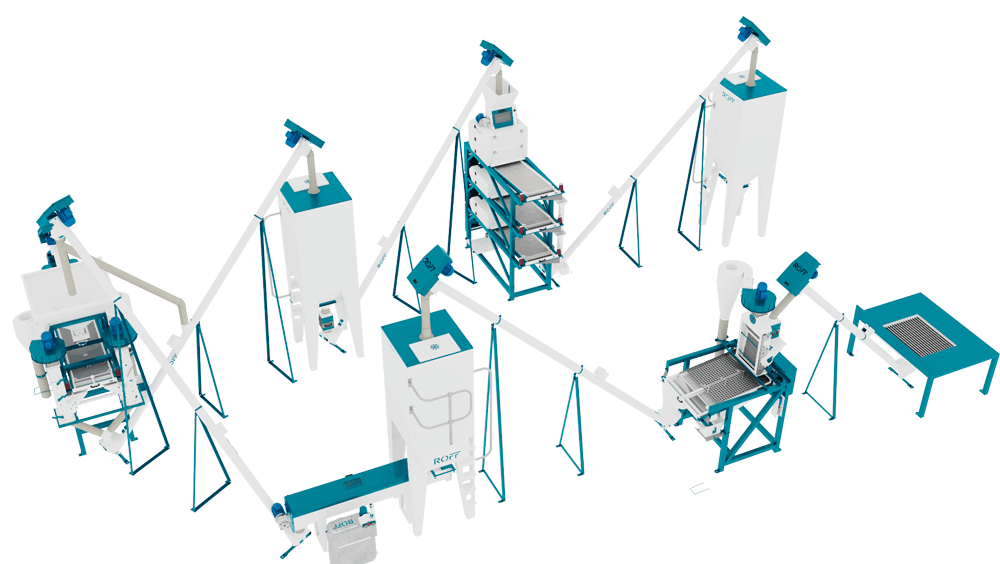

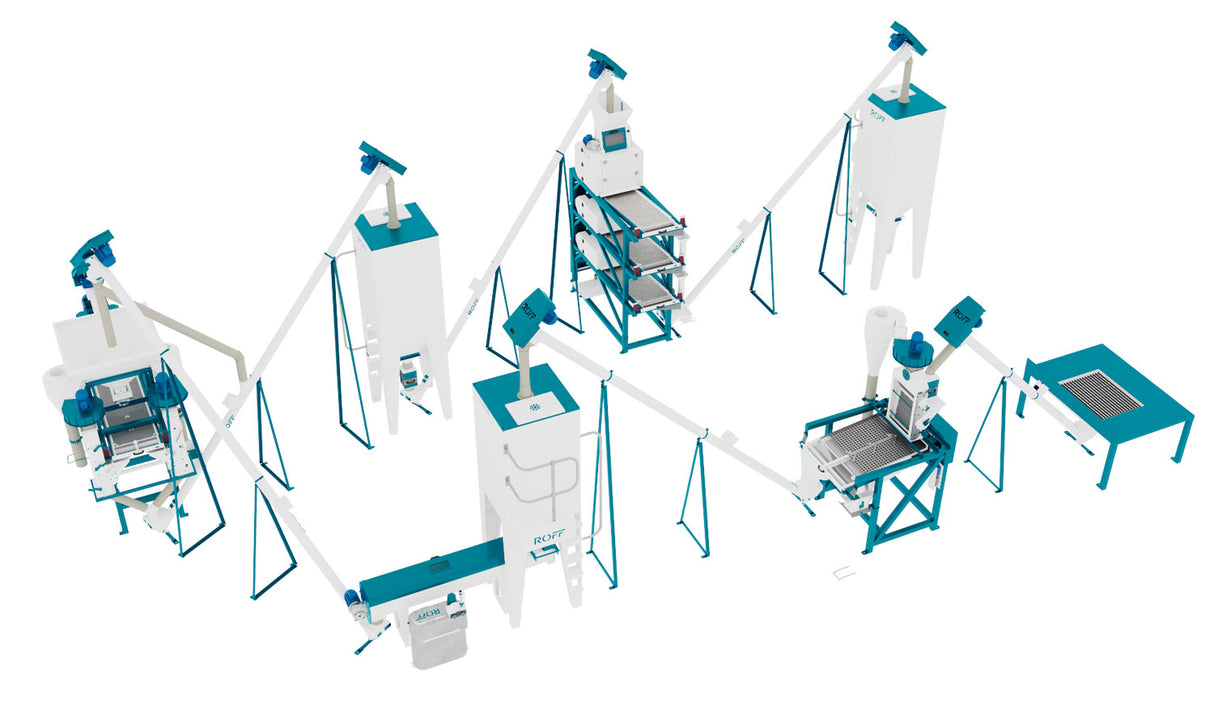

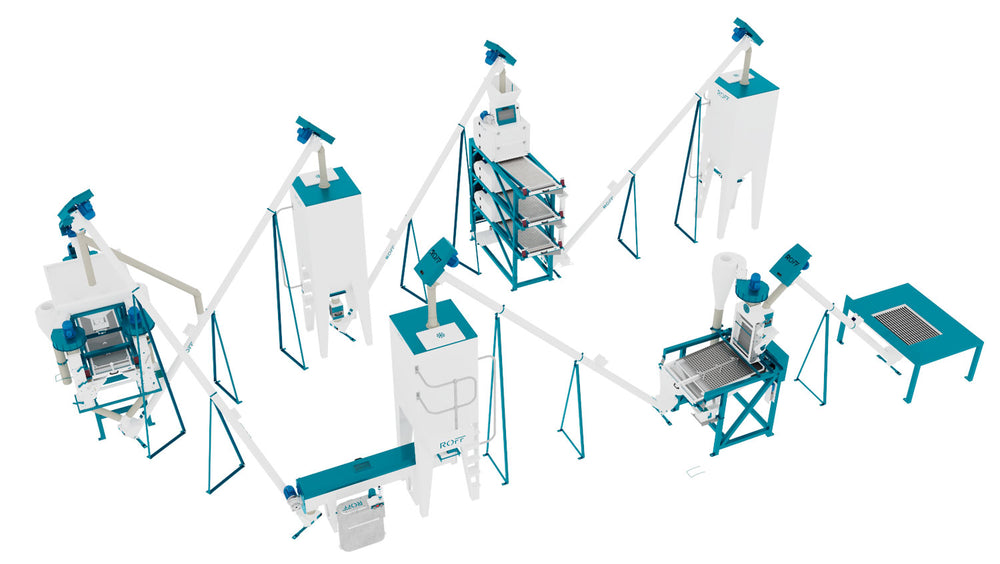

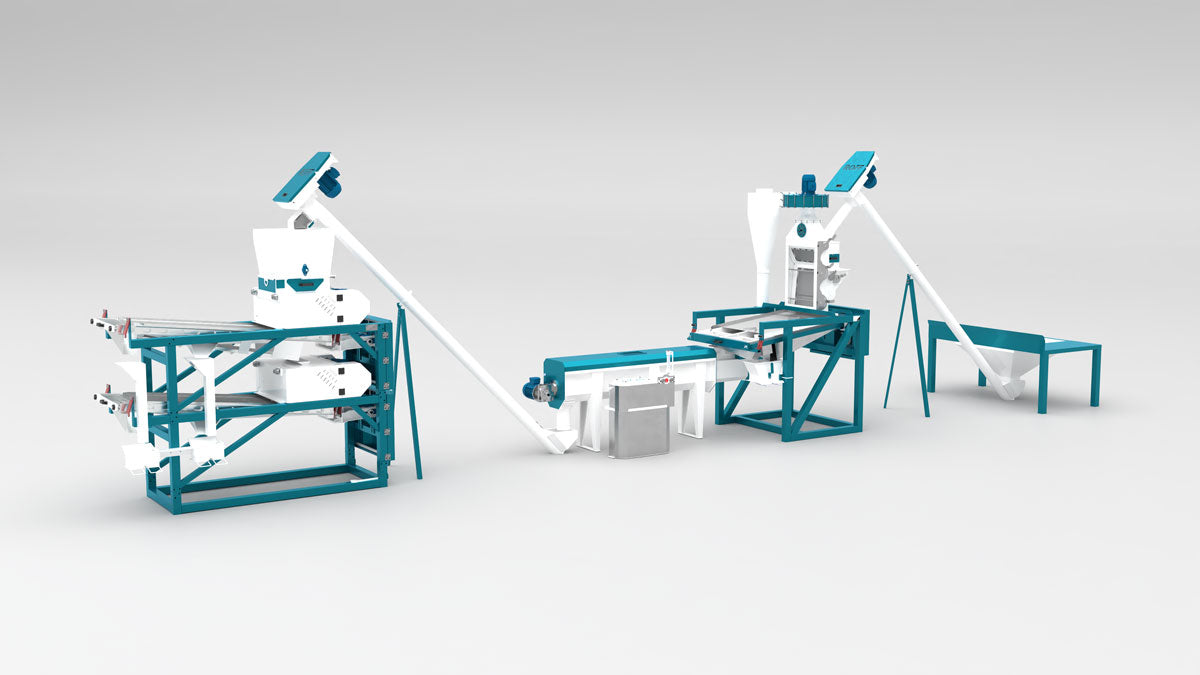

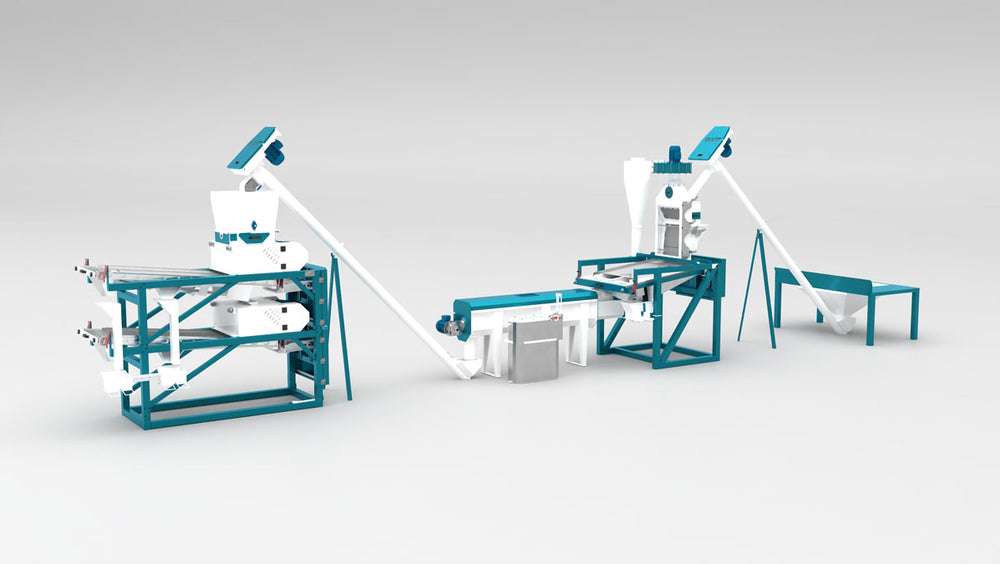

The SP-1 includes all the essential features and steps required to easily produce high-quality maize meal for ultimate profitability. You can produce high-quality, packed maize meal in four steps, namely cleaning, conditioning, degermination (optional) and milling. The Roff SP-1 milling plant is everything you need for an affordable commercial milling upgrade that will help drive your success in the maize milling industry.

Steps to upgrade: practical and cost considerations

The Posho or MK2S roller mill can be upgraded to a SP-1 maize mill by making the following additions / adjustments:

MK2S:

MK2S upgrade to SP-1 Core 650kg per hour mill:

MK2S upgrade to SP-1 Edge 1 ton per hour mill:

The Posho or MK2S roller mill can be transformed into an SP-1 Core maize mill through strategic modifications, including upgrading intake, cleaning, conditioning and milling processes. With an investment of approximately ZAR 375,000 - 485,000, this upgrade allows for the milling capacity of up to 18 tons of maize meal per day, depending on whether your existing setup is based on a Posho or MK2S roller mill. Some markets require a finer end product, so additional equipment will be required. A word of caution: as mentioned earlier, Roff recommends using the MK-6 roller mill as the foundation for your new SP-1 mill for a higher quality end product, as the production of Posho and MK2S roller mills is limited to Sifted or Special maize meal.

Have a look at the SP-1 maize mill.

Turnaround time

The installation, commissioning and training of the mill can be completed in only three days, allowing you to start your milling journey in record time. It was designed with growth in mind and can easily be expanded on at any time with a range of optional extras.

To discuss how you can go about taking this exciting step, contact Roff Milling at sales@roff.co.za.

The benefits of upgrading to a SP-1 maize mill:

- Economies of scale - profitability

- Lowest overhead costs per ton produced, compared to larger mills

- Higher quality product - meet customer expectations

- Access broader market

- Higher capacity

- Increased efficiency

- Employment creation - to the benefit of the community

- Funding support*

*Lesotho: Government support through the SADP

In conclusion

Community milling requires less initial capital and space but has lower output, whereas commercial milling demands more funds but reaps higher profits due to economies of scale. Upgrading to the SP-1 maize mill becomes vital for entrepreneurs seeking sustainable growth, improved productivity, and increased market reach.

When you're ready to make the change, expanding your milling operation to include an SP-1 in addition to from your current Posho or MK2S milling setup to a more profitable and efficient commercial SP-1 maize mill is not just a possibility, but a strategic move for long-term success. In the next blog in this series, we'll delve into how the Lesotho government, through the SADP, is fostering growth in commercial milling, along with essential aspects like storage safety and product quality testing. For more information, contact Roff Milling at sales@roff.co.za

2 comments

Dear all

I’m into maize production business, I have two old maize processes machine, I would like to know with prices the process to upgrade from community machine up to commercial. And I would like to know if it’s possible to arrange a visit on your site and one of your clients which did that upgrade.

Regards

Regards

———

Roff Milling replied:

Hello Edson, our sales team will get in touch shortly. Regards

Given the current economic benefits I think it’s a great investment and good for employment creation keep it up

———

Roff Milling replied:

Thank you John.