IT'S TIME TO FIND YOUR COMPETITIVE ADVANTAGE IN MILLING: ROFF’S C-80 MILLING SYSTEM VS. CONVENTIONAL MILL

Roff was established in 1991 manufacturing affordable, high-quality maize milling plants and crusher mills to the Sub-Saharan market. Since then, Roff has grown in size and so have our mills and offering. Although the values that guided us in those early days of affordability, compactness, value for money and quality remain the same.

Now, commercial clients rely on us to meet all their milling plant needs as a supplier and project manager.

The commercial maize industry in South Africa still follows the traditional model: producers, the farmers, sell the maize to silo owners who market and sell the raw maize to millers or animal feed producers. Once milled into maize meal or livestock feed and packaged, the product enters the retail or wholesale market and finally reaches the end consumer.

Roff helps farmers by giving them the ability to cut out the middle men, and bring in another revenue stream by expanding into the production of maize meal themselves instead of relying on others and forgoing that income. Farmers are not millers though, so they need a solution that suits their needs without the steep initial investment in starting a new business.

IT'S TIME TO FIND YOUR COMPETITIVE ADVANTAGE IN MILLING: ROFF’S C-80 MILLING SYSTEM VS CONVENTIONAL MILL

1. MULTI-PRODUCT MILLING

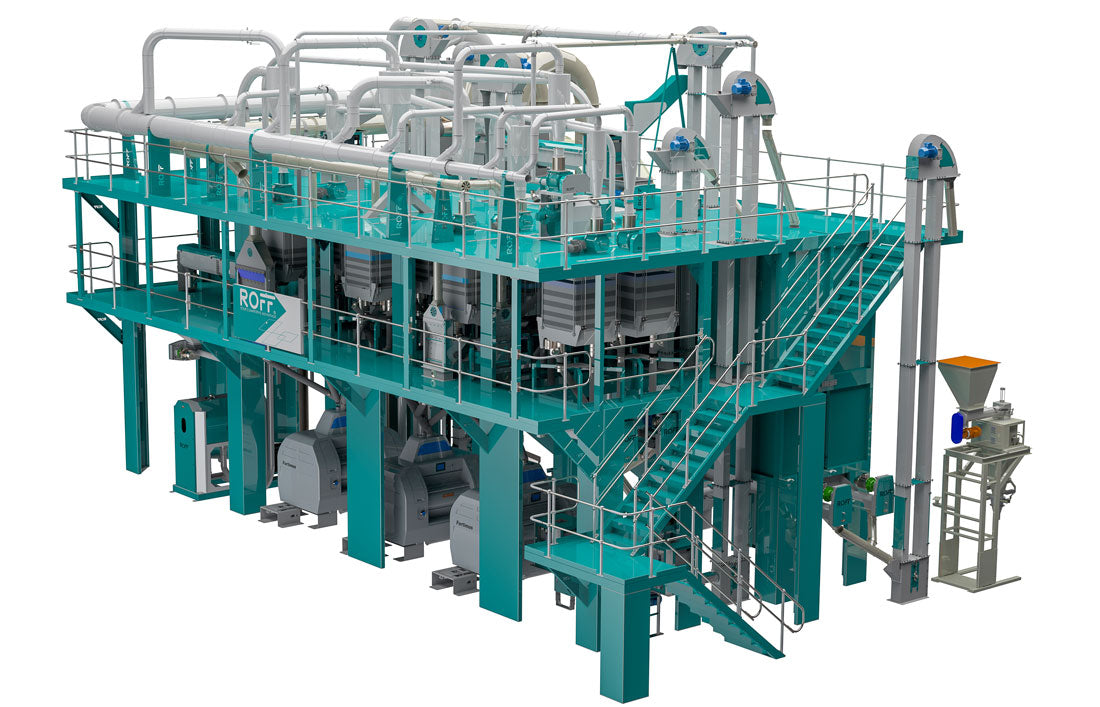

Roff’s C-80 mill is an all-in-one modular 5 ton/hour mill capable of producing two grades of maize meal, or it can be designed as a grit plant.

2. COMPACT

The C-80 is one of the smallest commercial industrial mills available with a footprint of 20 m (l) x 10 m (h) x 10 m (w). Don’t lets its size fool you, this plant was designed to compete on a national level, producing two maize products at a time.

3. SUPERIOR PERFORMANCE

The C-80 ensures 70% - 74% extraction rate, surpassing the industry norm of 68% - 70 %, depending on the country and maize quality. Not only that, it’s can produce two grades of maize meal or as grit plant for animal feed. The C-80 manages to outperform its competitors using sophisticated computer systems to optimise capacity and extraction.

The C-80 uses accurate performance data monitoring via process weighers at different stages of the production process to monitor capacity and extraction rate through the mill. We also made it easier to manage, with automated controls that make it possible for one supervisor and a team of two packer to run the C-80 around the clock at the standard 5 ton per hour configuration.

Roff drives success for our clients milling business. We see our clients as partners. Which is why after commission, delivery, installation, training and final handover of your mill, we offer regular service visits to minimize breakdowns and ensure operation at full capacity.

2 comments

Quote and delivery of the roff c-80 mill urgently required.Left message at your reception on friday. My contact nr 0824139958.CH Engineering projects

———

Roff Milling replied:

Hello Charlie, our Sales team will get in touch shortly.

Good day may we have the quotation of the above machine,

Regards

National Brakes and Clutch

+263 773 563 101

———

Roff Milling replied:

Hello, our sales team will get in touch shortly.