With all the challenges farmers face in Africa, climate change is one of the biggest threats. Increasingly severe weather is shrinking crop yields year on year and causing price fluctuations in the market, threatening the livelihoods of farmers.

One way farmers are securing their future is by moving into the maize milling business themselves to bring in another income stream.

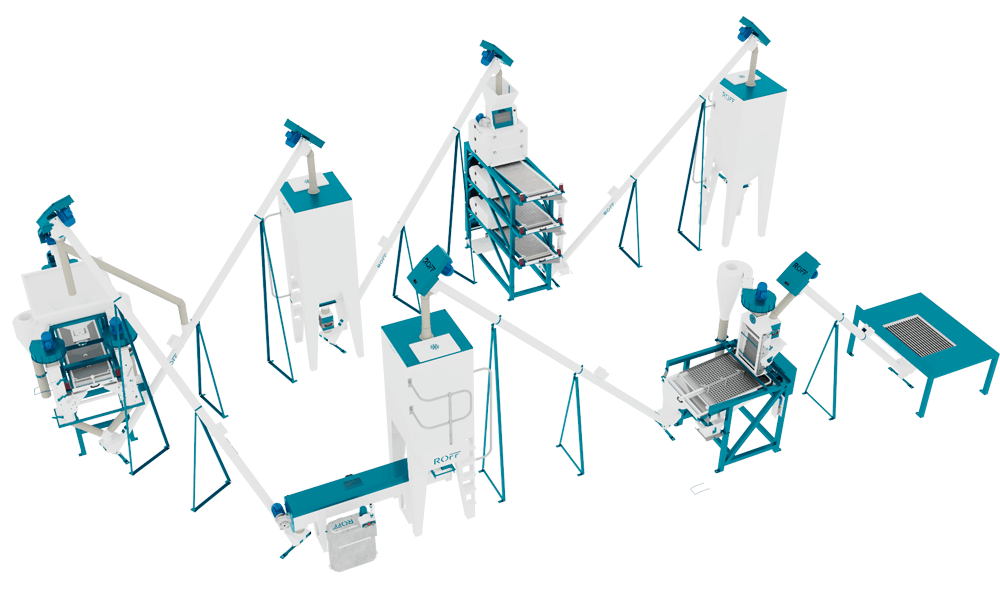

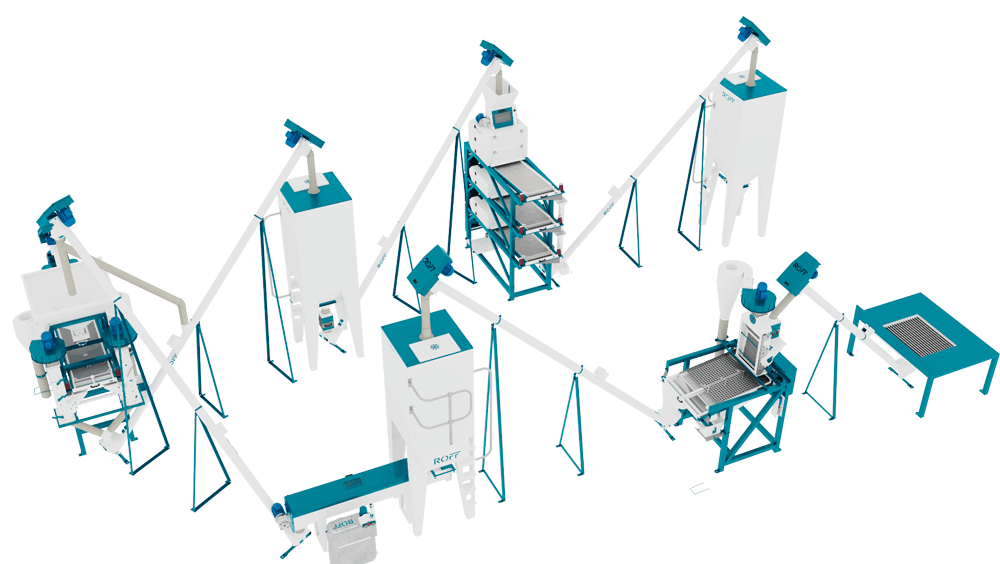

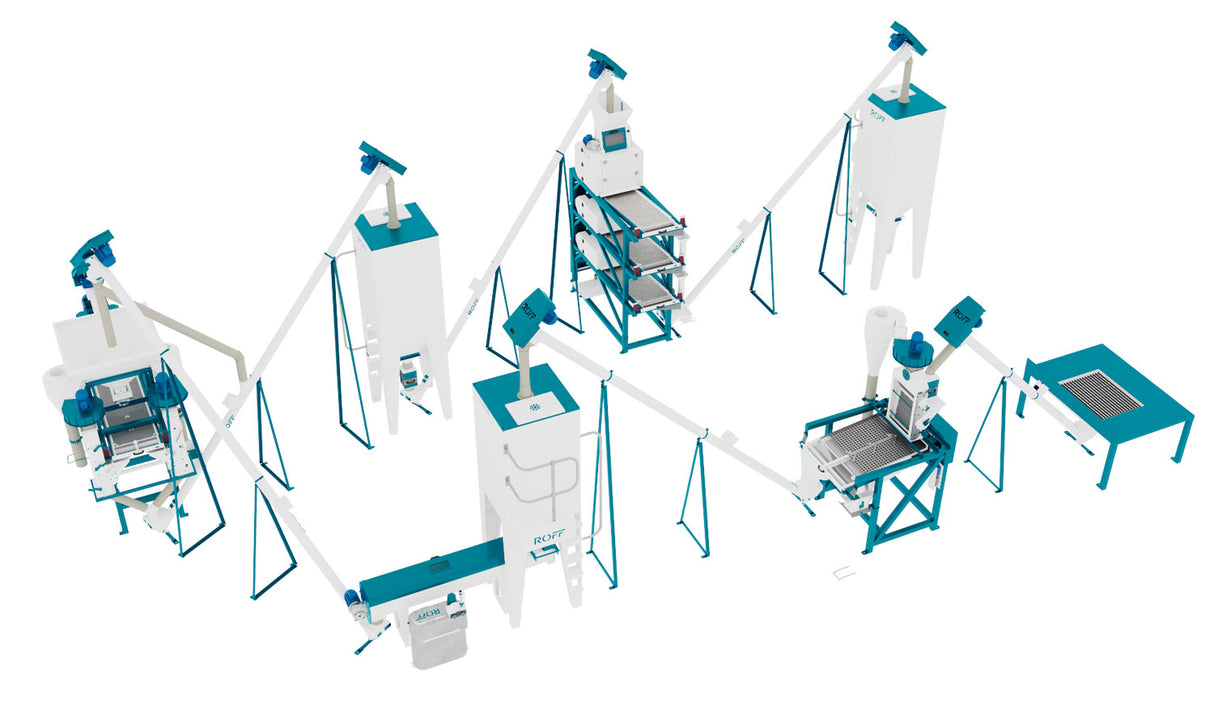

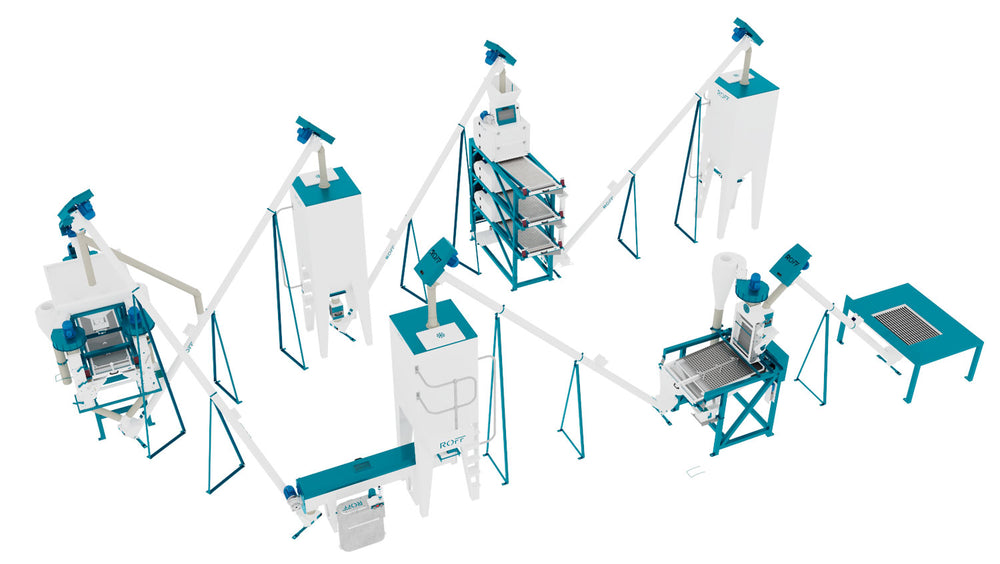

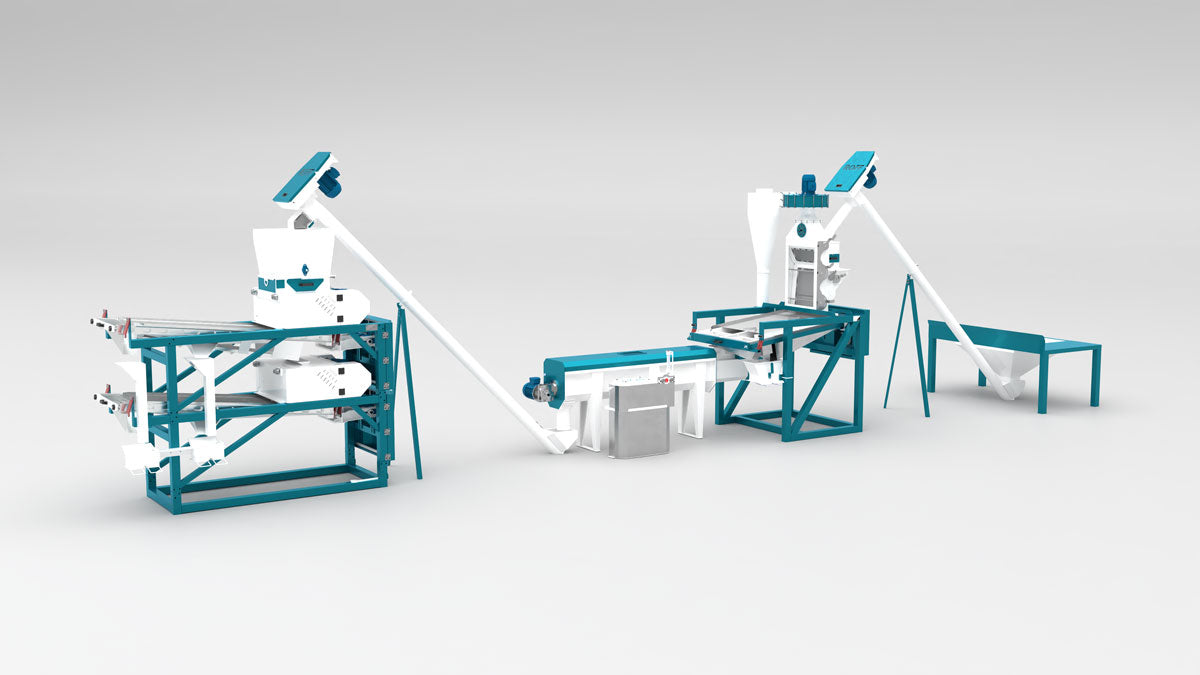

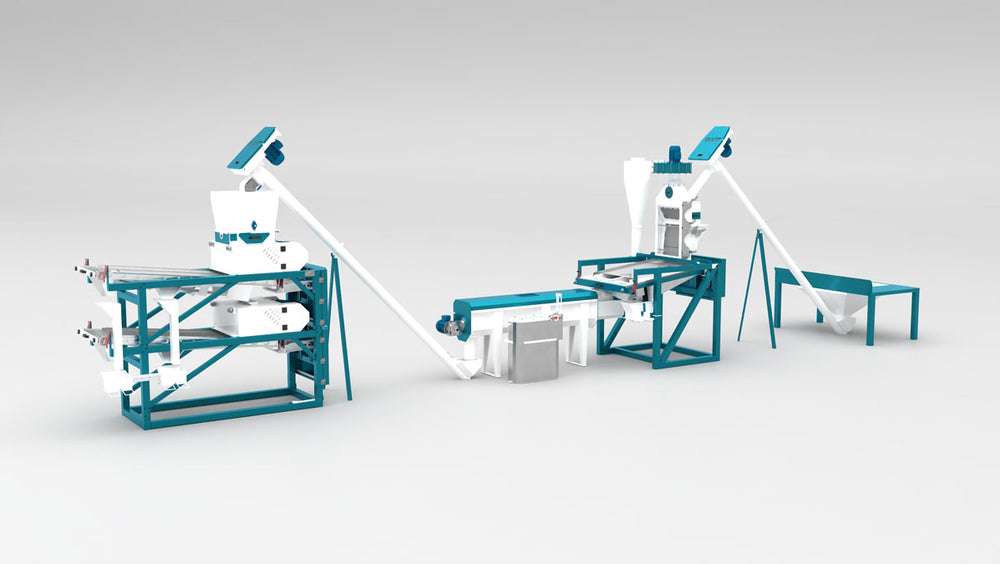

Starting any new business is a daunting task, but Roff’s SP-1 maize mill can help farmers enter the maize milling game. Here’s how:

EVERYTHING YOU NEED TO PRODUCE MAIZE MEAL

Roff’s SP-1 mill is everything you need to start milling high-quality maize meal and/or produce stock feed and from arrival at your site, it can take as little as two weeks to set up. We simplified the milling process to its core stages: cleaning, conditioning, degermination and milling, - making it possible to produce high-quality maize meal without a massive upfront investment.

EXTRACTION RATES ARE THE KEY TO PROFITABILITY

To maintain a competitive edge in the maize milling industry, small and medium-scale millers and entrepreneurs need to invest in a well-priced maize mill with superior extraction rates.

The rate of extraction is the measure and quality of maize meal produced during the milling process. These rates affect the profitability of your maize milling business. The quality of raw maize, the process of milling and the type of mill you choose will determine your extraction rates and in turn, your profitability.

AFFORDABILITY

Roff is dedicated to affordability, value for money and quality from the start. We used our decades of experience and expertise to design a mill that outperforms the competition in every area. The SP-1 offers one of the highest extraction rates with the lowest overheads per ton of product milled. You’ll get more in return with less waste using fewer resources.

MAIZE MILLING MADE SIMPLE

The SP-1 is designed so that almost anyone could be trained to operate and maintain it at peak performance, 24 hours a day. It can fit into most existing buildings, and all the equipment is installed on one floor. It sounds easy, because we’ve made it easy.

DESIGNED WITH GROWTH IN MIND

Roff has been helping small to medium-sized milling businesses achieve success for nearly 30 years. During that time, we created an easy to operate mill that can produce the highest quality maize meal, with potential for seamless expansion as your business grows. The SP-1 breaks down the milling process into the four essential steps as a start, whilst a range of optional extras that improve capacity and quality can be added quickly and conveniently as the need arises.

CHOOSE A RELIABLE PARTNER FOR ONGOING SUPPORT

Roff has been around since the start of the 90s and has become the leading manufacturer of high-quality maize milling plants and hammer mills in Sub-Saharan Africa. Today, even large-scale commercial mills rely on Roff for their milling plant needs.

We have a dedicated support team ensuring we supply the most cost-effect equipment, and our own trained technicians travel to our clients to service and maintain it for them. Our expanded infrastructure also means we’re in a better position to supply cost effective equipment, spares and reduced turnaround time for our clients.

Extraction rate losses and downtime can be costly. So at Roff, we also offer clients scheduled on-site plans to do a comprehensive check-up on the mill, to minimise breakdowns or diminished efficiency.

Contact our sales team today on +27 56 212 2697 or sales@roff.co.za to order your SP-1 mill and enter the maize milling industry with a competitive advantage… right from the start!

1 comment

Sp-1 great