HERE’S ONE WAY TO BOOST EXTRACTION RATES

Maize meal is produced by milling maize kernels and separating maize meal and offal (bran and germ).

The price of maize meal is much higher than the price of maize, the price of the offal, on the other hand, is much lower than the price of maize. So, it makes sense, to be profitable, that we want to produce maximum maize meal and minimum offal. We call the percentage of maize meal produced from the maize the extraction rate of the machine. For example, if we can achieve a 75% maize meal from maize, then the extraction rate of the machine is 75%.

Maintaining an optimal extraction rate is a significant function of the maize milling machine.

ROFF’S R-70: BEST-IN-CLASS EXTRACTION RATE

FACTORS AFFECTING MAIZE MEAL EXTRACTION RATES AND QUALITY

The quality of the raw maize before milling, the type of mill used and milling processes are all critical factors to consider that determine and influence extraction rates. We also go into how you can achieve extraction rates that surpass the industry standard and in turn, increase your profitability.

The physical characteristics of maize influence the extraction rate from the grain and the quality of the maize meal. Constant issues with maize is that kernel size isn't always uniform, and the hardness of the endosperm may vary. You can determine the quality and value of maize by measuring the hectolitre mass, determining the hardness of the maize kernel, moisture content, foreign materials like dirt plus any damage to the kernels themselves.

Ideal maize for milling is of large kernel size, low moisture (below 12%), clean from foreign matter and has a hard kernel.

MOISTURE

To produce good quality maize meal we need to remove the bran (pericarp), germ and tip cap, we call this offal. In order to remove the offal, the maize should be conditioned before milling. Conditioning causes the bran to become elastic and detach from the endosperm to be removed easily by the machine that improves the quality of the maize meal.

Conditioning in a milling process improves the extraction rate and moisture content in the endosperm. The higher moisture level in the maize meal increases the weight and thus the profit. Double conditioning is more complicated than single conditioning, but it improves the conditioning process even further.

To ensure the highest extraction rate from maize here is how the various methods used to stack up.

- Zero Conditioning - fair quality, fair extraction rate, fair wear and tear on machines, easy to manage the process;

- Single Conditioning - good quality, good extraction rate, good wear and tear on machines, easy to manage the process;

- Double conditioning - best quality, best extraction rate, lowest wear and tear on machines, more complicated to manage the process

DEGERMINATION

A degermination process is when the bran and germ is removed from the maize kernel before the kernel is being milled. This process produces the most refined maize meal with most of the bran and germ removed from the maize meal. Although some regions don't require degermination, the process not only gives a white meal but also increases the shelf life due to less fat.

Since the degermination process removes the germ from the maize and most of the bran to produce a much more refined maize meal, a decrease in extraction rates can be expected.

Note: Double conditioning and degermination is not essential for all regions and all product specifications.

For further advice on these processes in your region, please contact our sales team.

HERE'S ONE WAY TO GET AN ABOVE INDUSTRY AVERAGE MAIZE MILLING EXTRACTION RATE MEET ROFF'S R-70

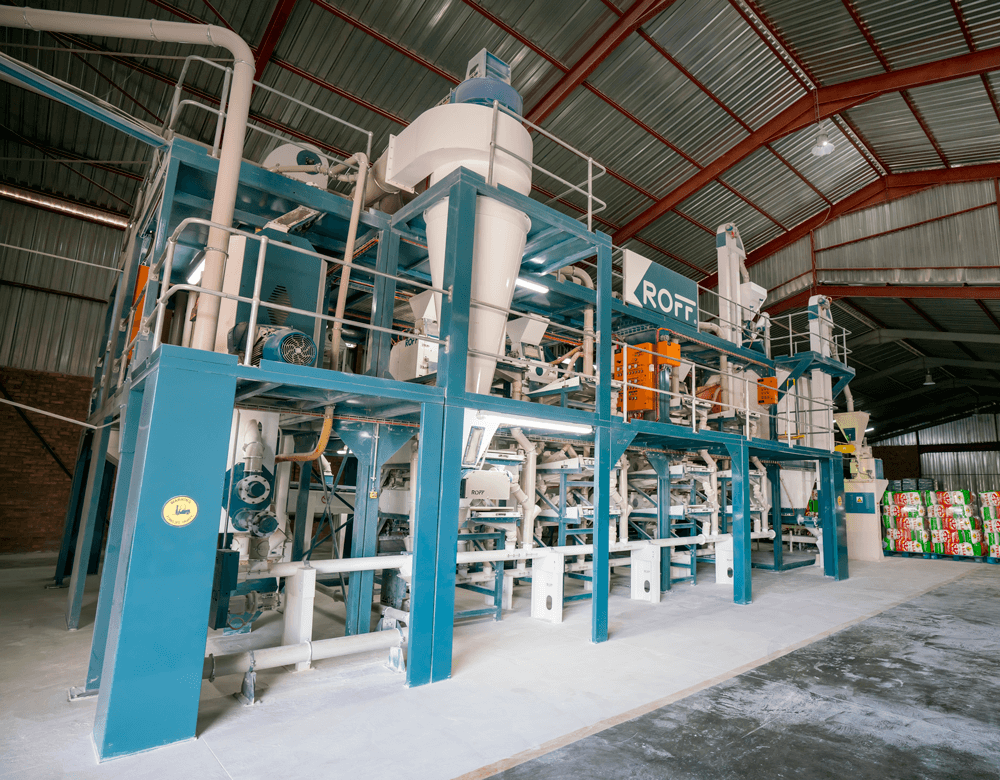

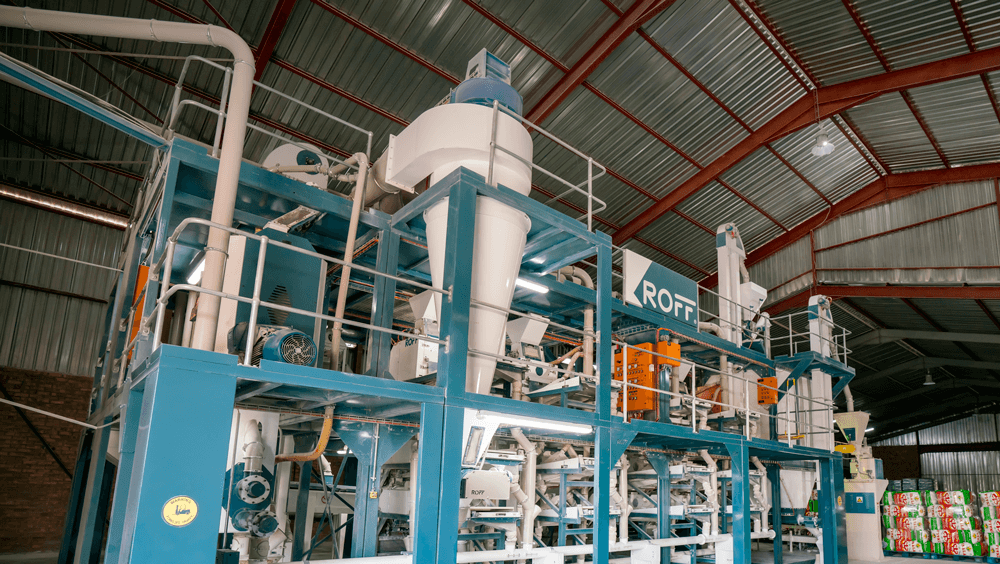

Roff has spent nearly a decade designing and engineering milling machines that surpass the industry standard. Roff's performance and reputation as it is in the industry made us ideal partners for the South African Grain Laboratory (SAGL). SAGL is a non-profit organization that provides unbiased, objective and accurate quality testing and standards for the agricultural industry in Southern Africa. SAGL asked Roff to assist in developing a Maize Milling Index Calibration for the industry, knowing Roff mill's reliability and performance would be the best possible reference method.

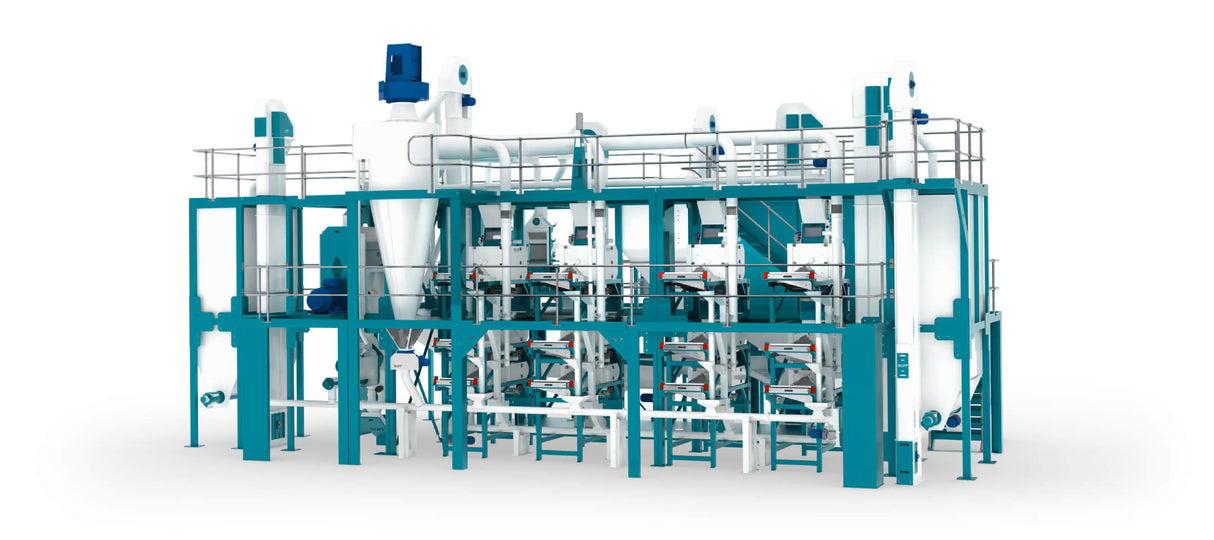

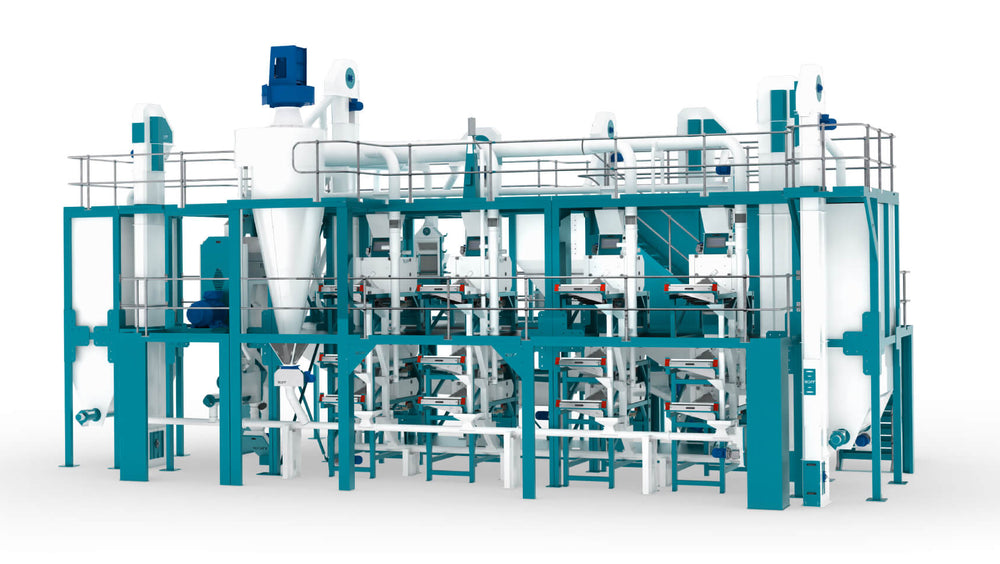

The R-70 is a compact, all-in-one mill developed as a cost-effective means for entrepreneurs entering the maize industry yet easily upgradable to compete on a national level. The R-70 allows you to produce 50 to 100 tons of super or special maize meal per day depending on the maize quality and in which country.

At Roff, we pride ourselves on delivering milling machinery that outperforms conventional milling plants. But, machines that are also compact enough to be housed in existing buildings without the need for any special requirements. The R-70 has two levels yet is only 6.8 metres high and takes up 112 square meters. All you need to provide is a building, water and electrical supply. The compact design also makes viewing all the critical stages during operation easy for a single supervisor.

If you're unsure which mill you should choose to suit your needs, take our quick, easy survey and narrow down the perfect mill for your business.

1 comment

Kindly quote us on this machine