Maize is the most widely grown crop in sub-Saharan Africa, and is a staple food for an estimated 50% of the population.

Key countries that dominate maize production in their regions are South Africa in Southern Africa, Nigeria in West Africa, Ethiopia in Eastern Africa, and Egypt in North Africa.

This blog takes a look at why producing maize meal in Africa is a sound business opportunity, the challenges faced by African producers, and some of the corrective measures that could be taken to increase the growth of maize in Africa.

THE GLOBAL PICTURE

Every year, 2.6 billion tons of cereal is produced globally. Of this 2.6 billion, maize constitutes 1.3 billion, followed by 750 million tons of wheat and 480 million tons of rice.

Although the top 10 producers vary from year to year, the United States of America, China and Brazil are consistently among the world’s largest maize producers. The Americas and Asia account for over 80% of the global maize production. The USA produced 33% of the world’s global maize in 2017, making it the world’s largest maize producing country.

THE AFRICAN PICTURE

- Africa accounted for 7% of global maize production in 2017 with 84.2 million tons produced.

- Maize occupied close to 24% of farmland in Africa – more than any other crop.

- 37 million hectares of maize was planted in Africa, 20% of the total global planted area.

- South Africa, Nigeria, Ethiopia and Egypt produced 51% of Africa’s total maize output in 2017. South Africa alone contributed 20% of this percentage.

YELLOW VS. WHITE MAIZE PRODUCTION

Yellow maize

Yellow maize is by far the most popular variety, accounting for 95% of the maize produced. Its kernels have a lower water content than white maize kernels and are harder. It’s used mainly for animal feed, especially for feeding poultry. The USA is the biggest global maize producer, with 99% of its output being yellow maize. In 2017, global production of yellow maize was 1.2 billion tons.

White maize

Since it is harvested earlier than yellow maize, white maize kernels are softer and have a higher sugar to starch ratio. White maize is crucial for ensuring food security in developing African countries, as it’s mainly used for human consumption. Argentina, Brazil and China account for 60% of the total maize output in the developing world, 60% of which is white maize. About 65 to 70 million tons of white maize is produced every year, representing 5% of the annual global production.

WHY PRODUCE MAIZE IN AFRICA?

First things first, why maize?

-

Maize is a staple for all, regardless of social standing or class. Although preparation differs from country to country, maize is a key ingredient in many African meals. Think ‘pap’ in South Africa, Ugali in Kenya or Kokoro in Nigeria. Lower income consumers may grow their own maize, or buy it from local markets, while upper income consumers buy packaged, branded maize from supermarkets.

- Significant potential to commercialise maize production. Businesses and manufacturers can invest in smallholder operations, thereby giving them access to better resources like bigger plots of land so they can increase their output. Investors could also partner with the value-chain stakeholders like farmers, farmer co-operatives and market associations to ensure that the harvested maize reaches the processing stage with minimal losses.

-

With support from African governments, long-term growth can be achieved. Governments can set up agricultural schemes to financially support maize farmers and increase farmers’ production capacity and yields. Import taxes and tariffs could incentivise local production, and encourage individual and industrial end-users to buy local products.

CHALLENGES FACING SUBSISTANCE MAIZE PRODUCERS IN AFRICA

Growing maize on the African continent is not without its fair share of challenges. Subsistence farmers, who make up the largest portion of maize producers, lack access to agricultural resources like fertilisers, seeds, machinery, warehousing facilities and vehicles, negatively impacting their yields. Maize is also grown on smaller plots and not commercially produced on a large scale, due to a lack of resources.

Maize growth potential is limited by:

Input supply

- Low yielding maize varieties – this is caused mainly by poor funding of agricultural research institutions

- Expensive inputs like fertilisers

- Inconsistent access to inputs such as agrochemicals

Farming

- Small farm plots (<2 ha), traditional farming practices and poor irrigation

- Low/no access to machinery

- Diseases, weeds, pest and rodent infestations

- Lack of transport to end-market so some farmers rely on exploitative middlemen

Processing

- Insufficient raw material inputs arising from low yields and post harvest losses

- Lack of capital and necessary processing equipment for large scale processing

- Infrastructural deficiencies like erratic power supply and water shortages leading to high overhead costs

Distribution

- Lack of vehicles and poor roads

- Limited warehousing facilities and high storage costs

End market

- Rising/fluctuating prices due to drought, low yields and high production costs

- Industrial end-users prefer imported products due to competitive prices and low grade of domestic products, e.g. ethanol and starch

Furthermore, as much as 25% of the maize crop is lost annually during various stages of production like harvesting, transportation to the farm, shelling, drying, farm storage, transport to the market, and market storage:

- Harvesting: 5% - Farmers harvest the maize manually, throwing the cobs on the ground to be collected later. This causes seed splintering and cob damage.

- Transport to the farm: 1.5 % - Farmers transport the harvested maize to the farm by carrying it on their heads, with grains and cobs falling to the ground, leading to losses.

- Threshing/shelling: 5% - When the grains are removed from the cobs (shelling), the maize grains splinter. These splintered grains must be removed because they are more susceptible to pest attacks and are unfit for storage.

- Drying: 6% - Drying maize grains results in grain spillage during spreading and packing, especially when it rains. Animals may also consume some of the maize, leading to losses.

- Farm storage: 7% - Insects such as borers, beetles and weevils, and rodents cause losses by attacking inefficiently stored grains, because farmers lack the right storage facilities.

- Transport to market: 1.5% - Grains are lost due to leakage from sacks and rain in transit when farmers transport dried maize on their heads or bicycles.

- Market storage: Temperature and humidity, sub-optimal storage factors, are the main reasons for losses during storage at market warehouses.

INTERVENTIONS TO HELP MAIZE PRODUCERS

With the right interventions however, from both the public and private sector, solutions to these problems can be found. And African entrepreneurs have proven their resilience and ingenuity time and time again.

Input supply: agricultural inputs and research

Governments can introduce efficient subsidy schemes for seeds, agrochemicals and fertilisers, and encourage the use of cheaper fertiliser substitutes like livestock manure and post-harvest crop waste. The public and private sector should help agricultural research institutions to develop high-yield maize varieties.

Farming: optimal arable land and mechanisation

Stakeholders should support efforts to increase the planting area (88 million ha of arable land is unplanted) to improve actual yield, reduce imports and boost food security. Crop-share farming could also drastically increase the yield from subsistence farms. They should also facilitate access to mechanised farming for small-scale farmers e.g. like the Hello Tractor model (see below).

Processing: Tailored agricultural lending and centralised maize collection

Maize processers should have access to flexible agricultural loans at low (single-digit) interest rates. Regional maize collection depots could be established so that farmers can directly supply their maize and eliminate exploitative middlemen.

Distribution: Infrastructural development

Infrastructural facilities for the route to market, including vehicles, roads and rail facilities, should be developed to limit wastage/crop losses along the maize value chain. In addition, by providing shared warehousing with similar grain goods, storage costs can be reduced.

End market

Once the maize value chain has been strengthened, governments should consider introducing higher import tariffs and taxes for maize and maize derivatives – especially from non-African countries – to encourage local production and consumption. Cross-border and intra-African trade of maize should also be facilitated.

COMMUNITY MILLING - A PROFIT-MAKING OPPORTUNITY FOR RURAL ENTREPRENEURS

Godfrey Kou, Jerry Ntsekhe and Mahala Molapo are three African entrepreneurs who saw a need in their local communities and heeded the call for community milling in Lesotho. Community millers get paid a fee to mill maize members of the community grow. Their success stories illustrate why one should not dismiss ‘community milling’ (also known as service or posho milling) as a business opportunity. It can grow into a lucrative empire. Learn more about the difference between commercial and community milling.

The maize production industry in sub-Saharan African is growing from strength to strength – and offers vast opportunities for dynamic entrepreneurs.

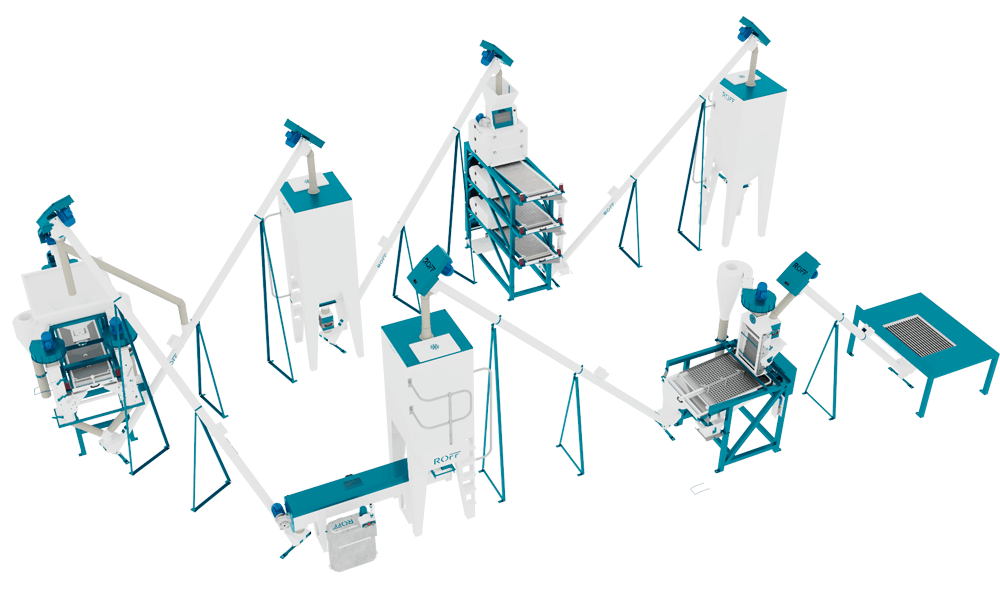

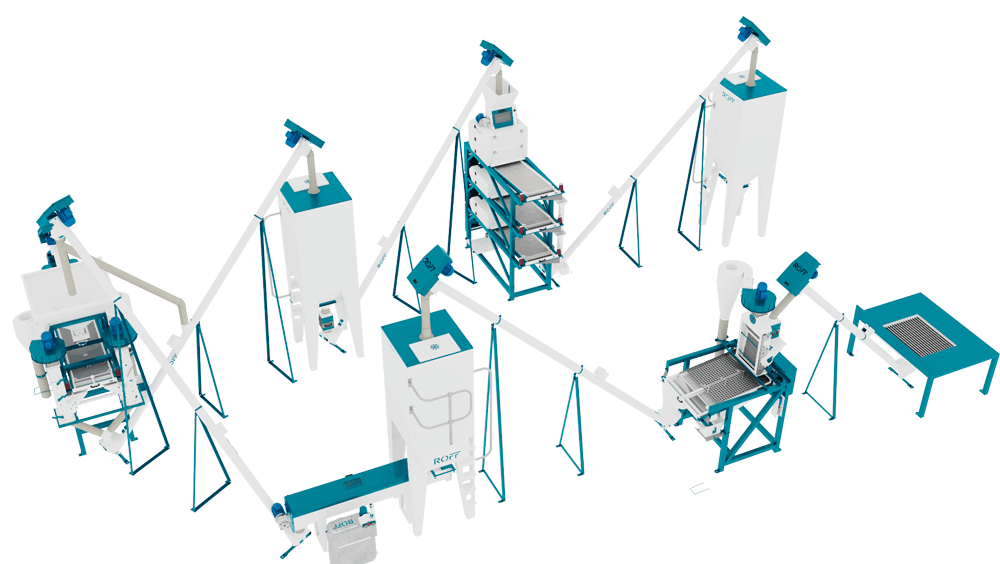

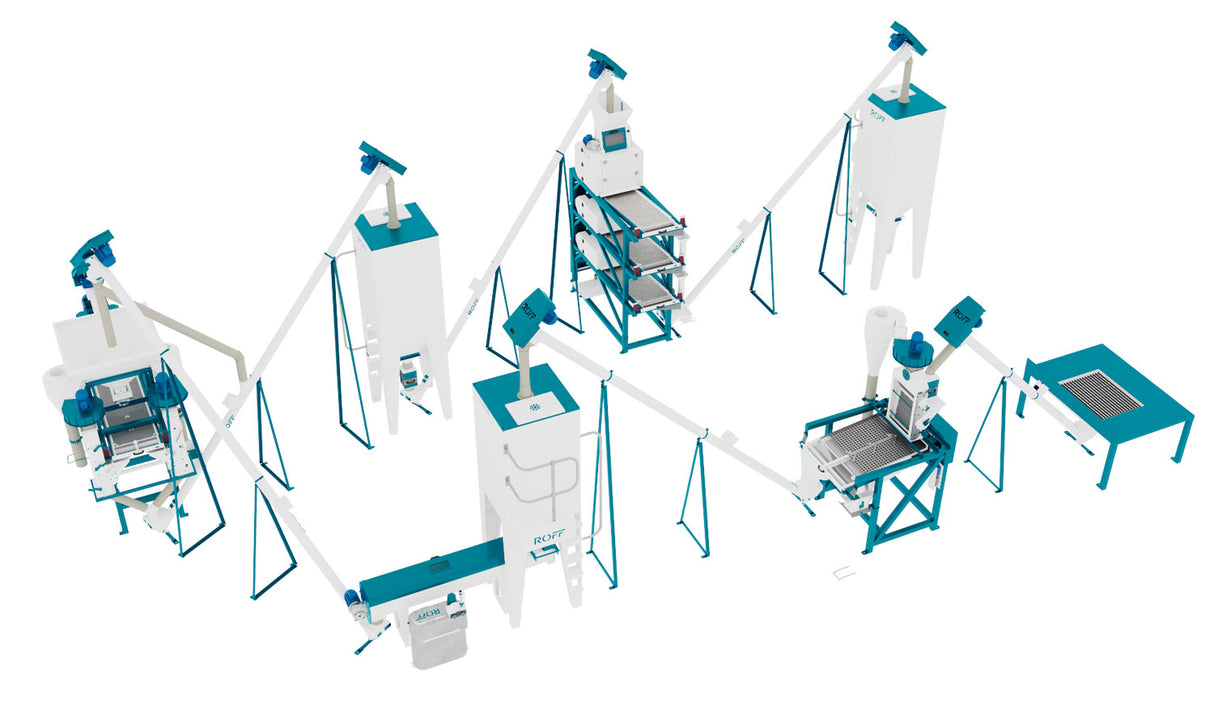

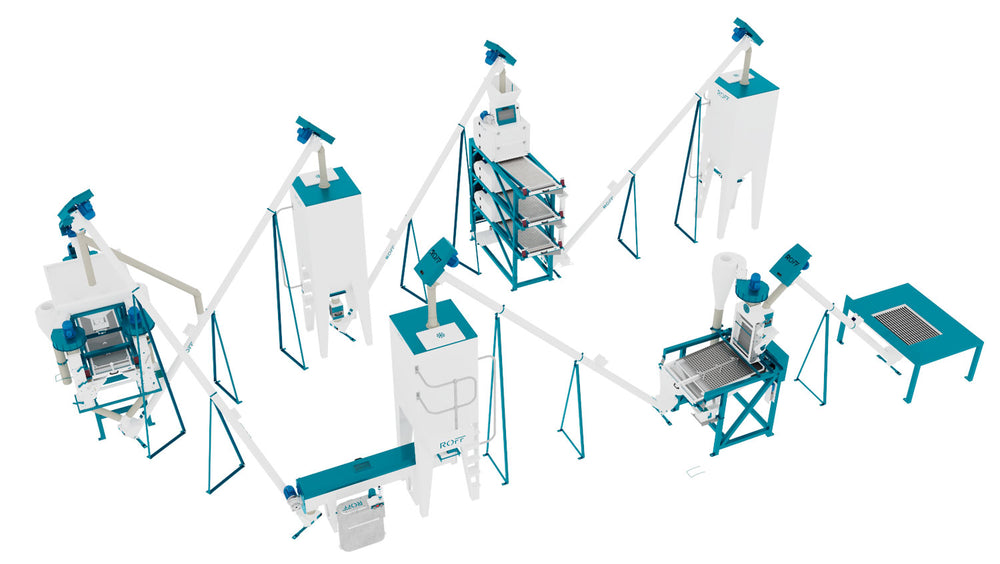

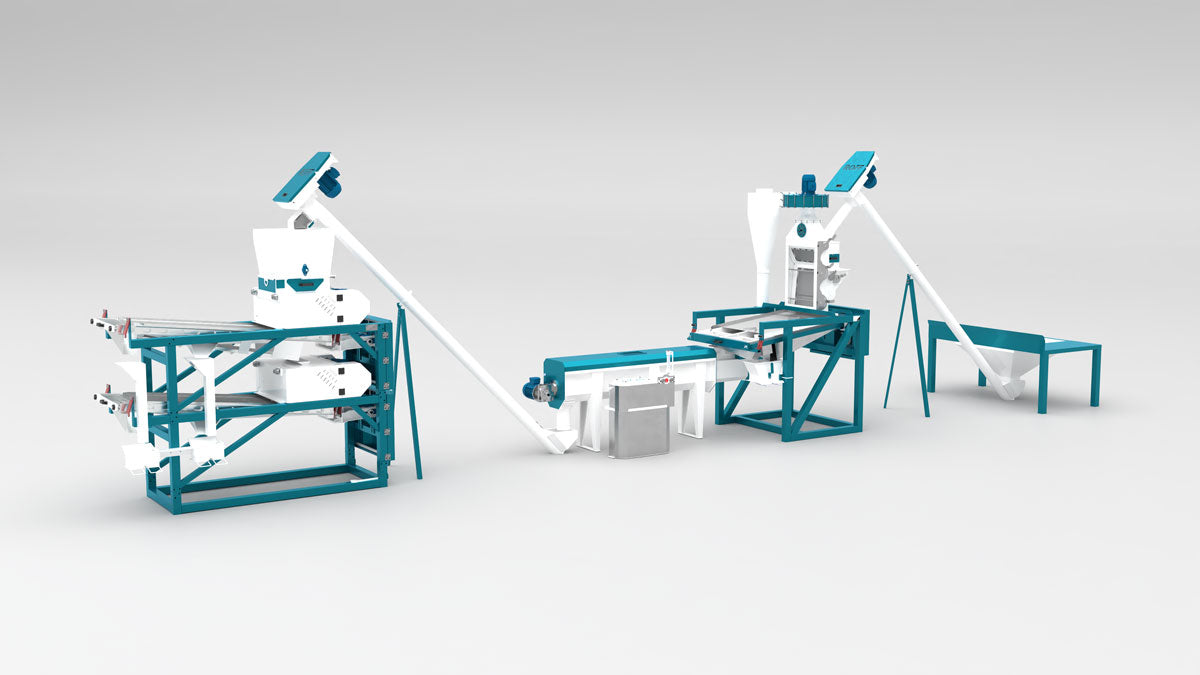

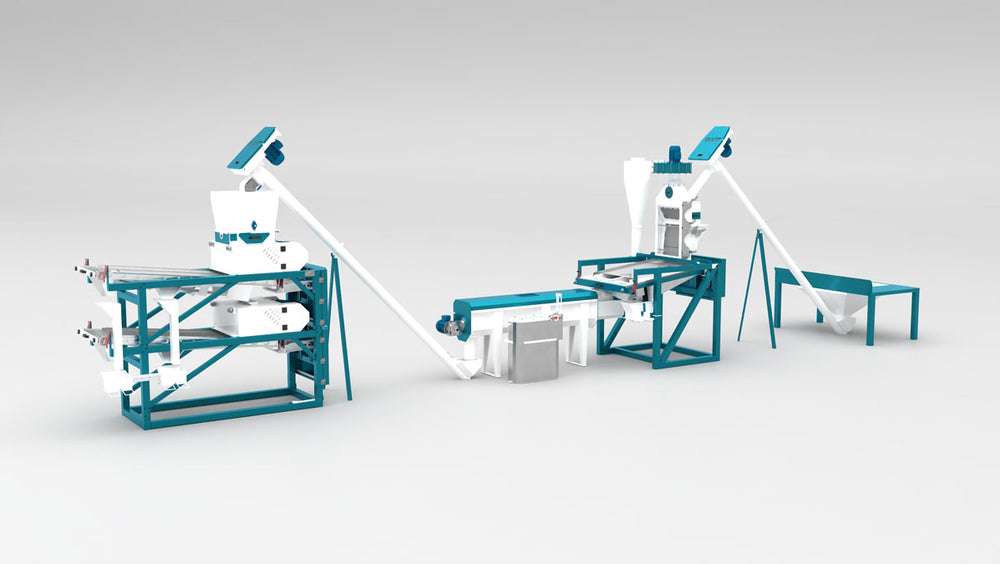

Roff Milling is dedicated to helping you, our client, with the advice, equipment and support you need to drive your success.

Source:

Maize Meal: A Look at the Ultimate Staple in Sub-Saharan Africa – report compiled by Euromonitor International

4 comments

Please connect me with Benjamin

———

Roff Milling replied:

Hello Stephen, please send us a email to sales@roff.co.za<mailto:sales@roff.co.za> for a consultant to assist. Regards

I’m enquiring for white and yellow maize Non-Gmo 50 000 Mt and 15000 respectively

———

Roff Milling replied:

Hello Abel, Roff is a maize mill manufacturer, we do not supply the maize itself.

I am looking for buyers in maize and sunflower busdiness i can supply in containers and in a high quantity.if you know of any body or a platform where i can sell please let me know kindly.

———

Roff Milling replied:

Hello Benjamin, Roff is a maize mill manufacturer, we do not sell or procure the products itself.

Please advise if I can purchase dry maize and maize meal from your company?

———

Roff Milling replied:

Good Day Shereen, thank you for your inquiry. Roff is a maize mill manufacturer, we do not supply the maize itself. Kind Regards