Roff has long focused on designing and engineering milling equipment to better match particular local needs. Roff's Posho Mill is the result of years of targeted research, to create a mill that serves as an accessible, lucrative entrepreneurial opportunity.

Localised maize milling is a rapidly growing market sector. Roff's Posho Mill seeks to provide entrepreneurs with a business that provides sustainable revenue, is easy to operate and service, and has low maintenance costs.

Here are 5 of the most crucial reasons why Roff's innovative Posho Mill is the perfect opportunity for savvy entrepreneurs in Africa:

01. MAIZE MEAL AS A STAPLE FOOD WILL ALWAYS BE IN DEMAND

For Africans, milled maize ties meals together day in and day out. It's the perfect staple food: filling, versatile, and seamlessly soaks in a broad range of additional flavours.

The Posho is where tradition and practicality meet. Whether the product comes from regional farming or the local area, demand for maize meal is an inevitable fact of African life.

THE CHALLENGE

Maize is grown in many regions of Africa, but because there are no mills, local farmers make very little income because of transporting maize to mills far away. At the same time, the price of maize meal becomes even higher for isolated, poorer communities because the meal has to be transported back to them.

This cycle of poverty is broken with the Posho, expertly designed for successful service or community milling. Community or service millers charge members of the local community a small fee for milling their maize. Bringing their maize to be milled is not only convenient but also more affordable than buying commercially packaged maize meal from shops. Typically, many Posho millers sell maize to the public, which they then can have milled.

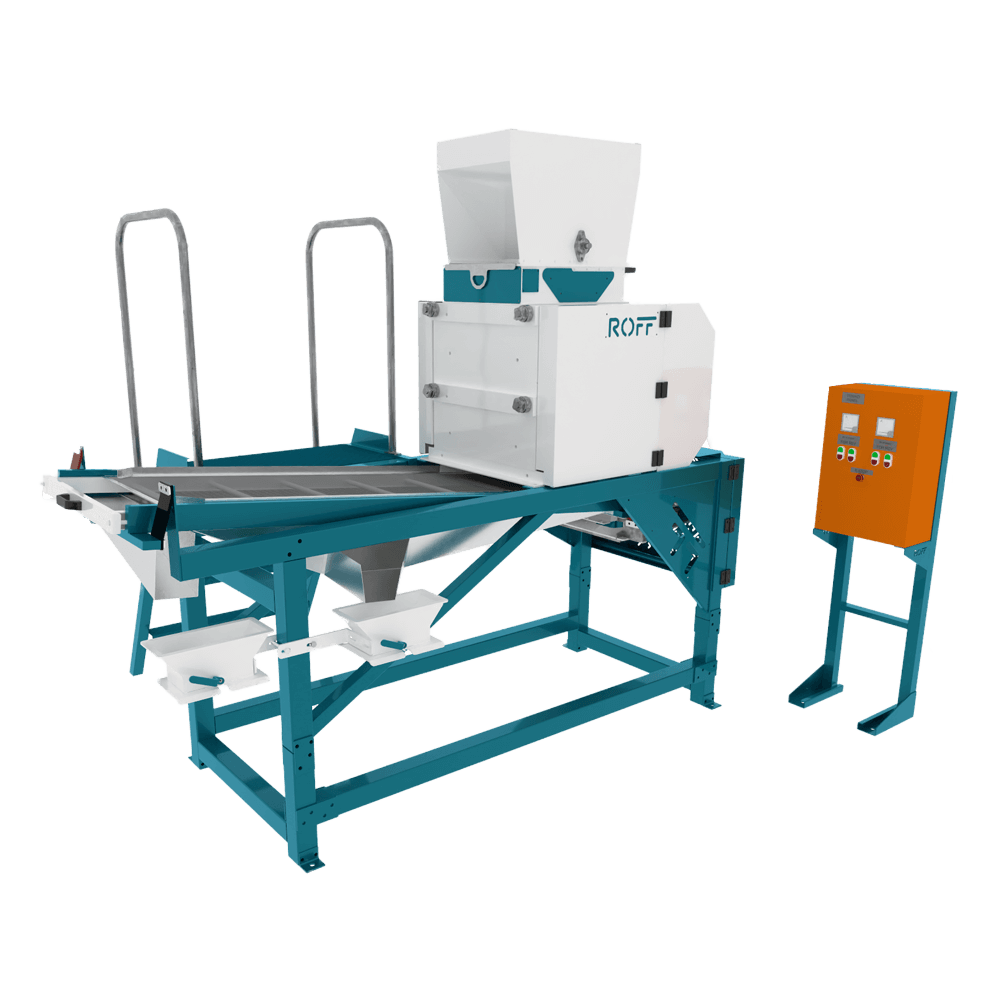

Join the ranks of entrepreneurs providing an invaluable service to their local communities while generating a profitable income. The Posho Mill is the easiest way to manufacture quality maize meal with its durable, compact design, simplified roller milling technology and hard work ethic.

With 2.5 to 2.75 million hectares of commercial maize produced in South Africa alone, there is no shortage of raw product in need of being milled into ready-to-cook maize meal.

THE POSHO SOLUTION

The Posho Mill creates a consistent result with a fine grain that improves the texture and overall flavour. So while there are inevitably local preferences in areas, the quality factor is the element that pushes up demand.

Roff accomplished this upgrade in quality by:

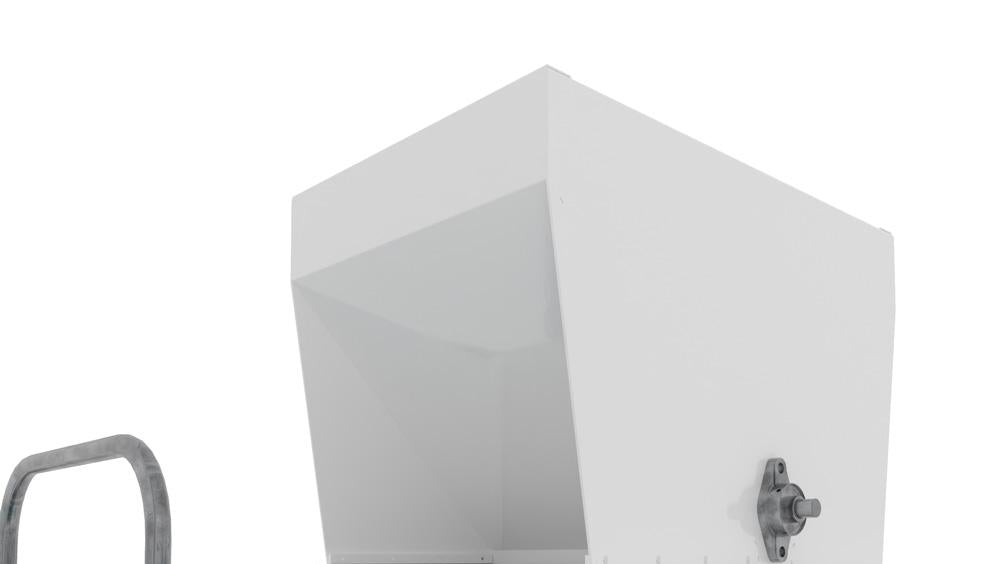

- Redesigning the hopper, a 50-litre unit with an agitator that creates the evenest flow possible

- The gate valve is simple to use, allowing the operator to control or stop the flow of product through the mill.

With even flowing maize creating an even grind before it enters the rollers, the eventual result when cooked is tastier, less gritty and stays fresher for longer.

2. POPULATION GROWTH MEANS CONSUMPTION GROWTH

So if maize meal, as a near-daily staple food, is in high demand today, where will things be tomorrow?

Most people love a quick buck, but the truly successful business owners develop an eye for where things might be years, even decades down the line. For milled maize, the future looks great.

Population growth looks to continue at a rapid pace worldwide, and the majority of it is projected to take place in Africa: 1.3 billion additional people by 2050.

That means rising demands for staple foods should remain a constant for many years to come. For those looking to invest in spaces that could continue producing profitable, positive growth results on a generational scale, milling maize is a prime opportunity.

When populations grow at a rapid pace, food production quickly becomes even more central to the local economy. Having an established, dependable maize milling business is a sure-fire way to sustained growth for the foreseeable future.

3. MAIZE MEAL FOR PEOPLE, BY-PRODUCT FOR LIVESTOCK

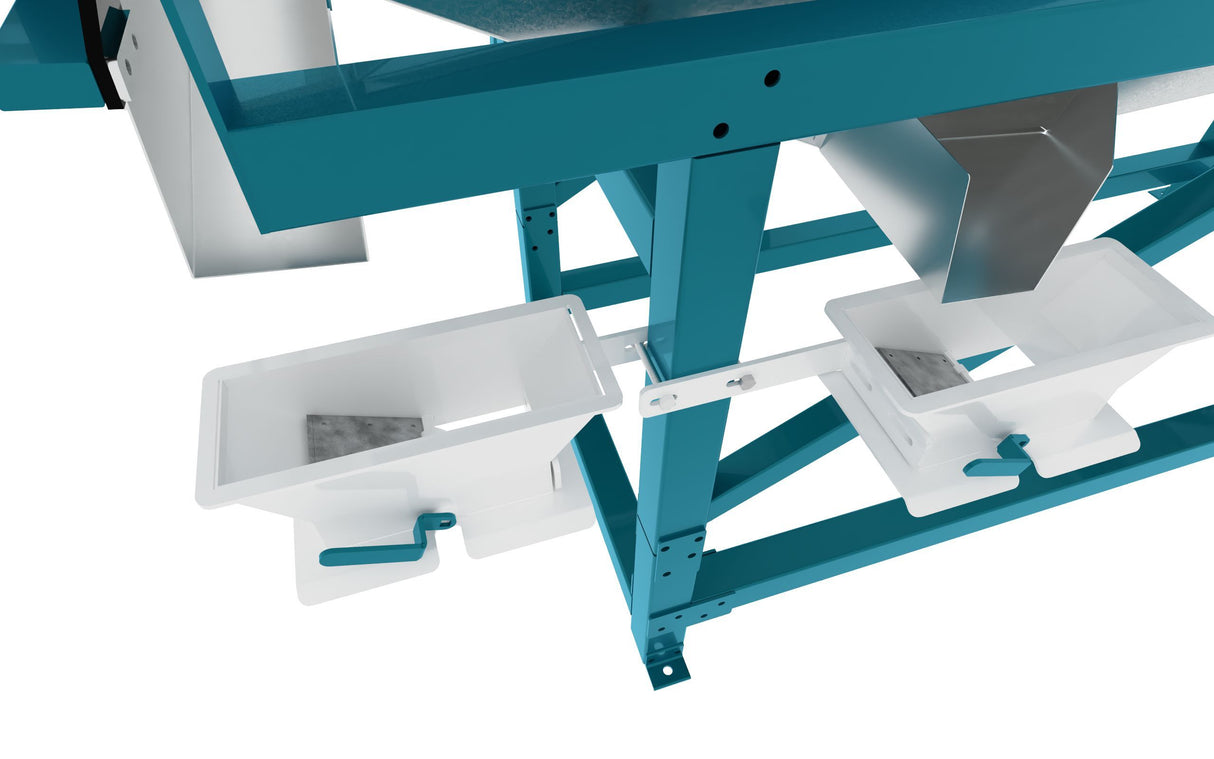

Roff's Posho Mill is designed to remove the coarse bran from the maize meal leaving better tasting maize meal. So you create two distinct, useful products during the milling process: 85% maize meal for human consumption, and 15% bran suitable for animal feed.

Mill operators can leverage this opportunity in many ways. You can either sell the bran as animal feed to farmers or, if you already have animals, the costs of buying feed can be drastically reduced or even eliminated by this continuous supply of top quality animal feed.

The versatility of maize milling by-product means there is constant demand from feed manufacturers who use it as part of their top of the line offerings.

Regardless of which of the above you choose, it's generally a good idea to develop relationships with food providers for both markets.

4. SCALABILITY IS CRUCIAL FOR AFRICAN DISTRIBUTION

One of the great difficulties of milling maize in Africa is distribution, keeping prices low when transporting. Profitability can erode quickly under the pressure of merely getting a product to market, regardless of its quality.

Roff's Posho Mill was designed with this exact need in mind. The Posho is compact enough to be installed almost anywhere, yet at 750kg per hour, the comparatively large production capacity makes it perfect for small businesses serving regional or even local markets.

Entrepreneurs can invest in as many of these streamlined, affordable units as needed. The Posho's compact design and ease of operation mean they can be commissioned and set up almost anywhere making distribution less expensive.

5. LOW OPERATING COSTS, FROM DAY ONE OF OPERATION

The Posho Mill is designed to limit as many overhead costs as possible while still maintaining industry-leading production efficiency and quality.

It requires only 9.5 kW of power. The results of this efficient operation add up to 82% to 85% extraction from 750kg per hour.

Setting up this cutting edge mill doesn’t take much effort. Absolutely no formal training is required, and the mill comes pre-assembled. All you need to do is power the machine and enjoy the results of the most advanced, small-scale maize mill currently on the market.

These mills are so easy to use that it opens up new opportunities, like charging a fee for locals to bring their maize to be milled. It is that accessible, safe, and simple to operate.

Roff’s engineers designed a mill guided by the needs of African investors to be able to build flexible and scalable businesses centred on producing high-quality maize meal. These are but a few of the proven benefits entrepreneurs enjoy by investing in Roff's Posho Mill. Satisfied customers get the best quality product on the market, and businesses increase their profits by savings on efficiency and higher yields - a win/win if there ever was one.

1 comment

Morning Sir! How much Roff posho mill?

———

Roff Milling replied:

Good Day, please have a look on our website https://www.roff.co.za/pages/posho-community-maize-mill or get in touch via email at sales@roff.co.za<mailto:sales@roff.co.za> Regards