To maintain a competitive edge in the maize milling industry, small and medium-scale millers and entrepreneurs need to invest in a well-priced maize mill with superior extraction rates.

The rate of extraction is the measure and quality of maize meal produced during the milling process. These rates affect the profitability of your maize milling business. The quality of raw maize, the process of milling and the type of mill you choose will determine your extraction rates and in turn, your profitability.

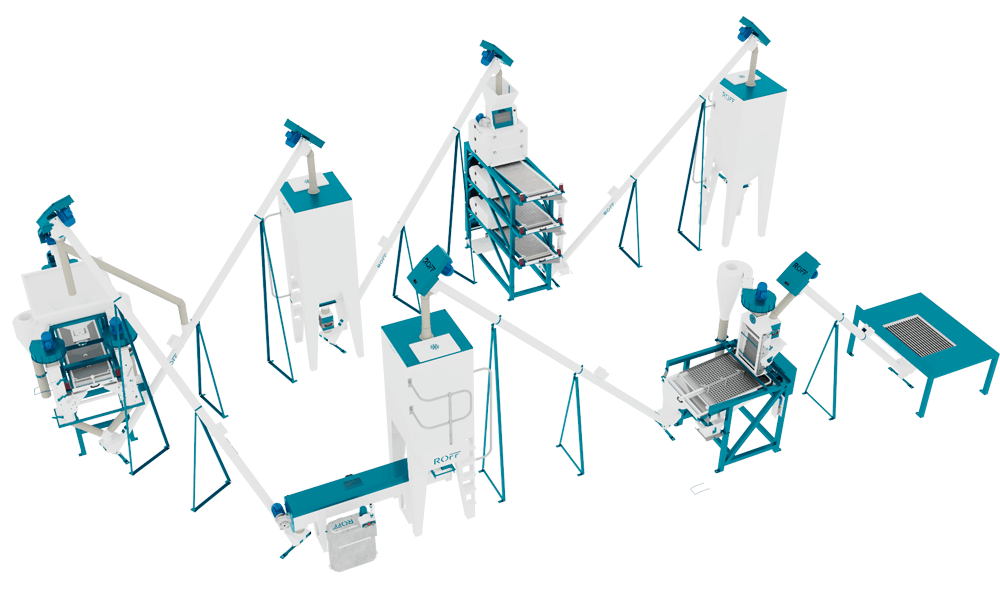

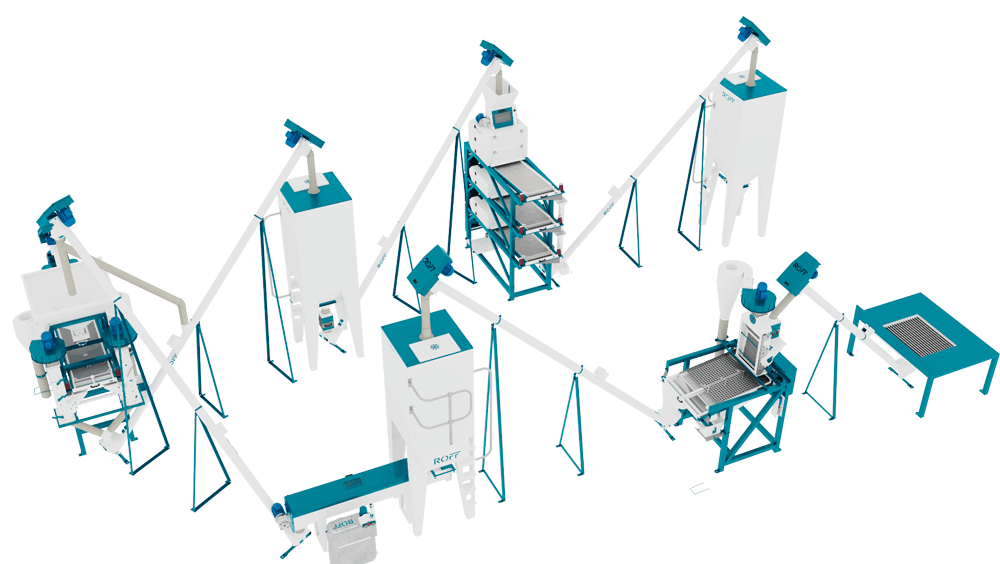

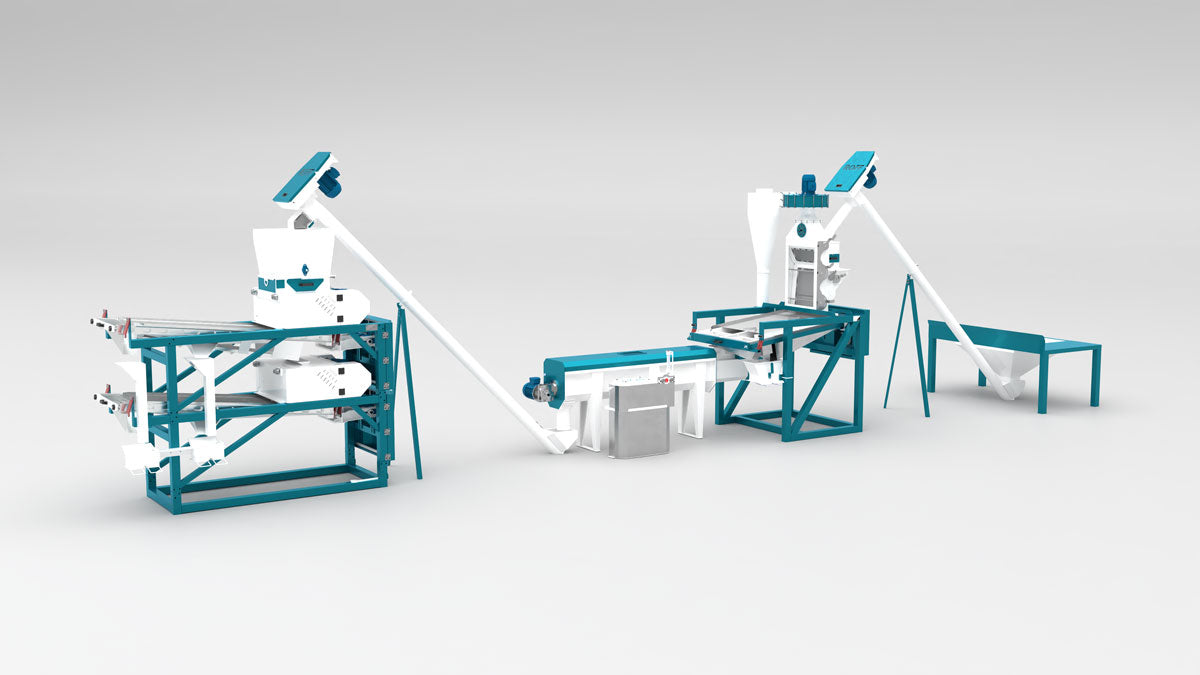

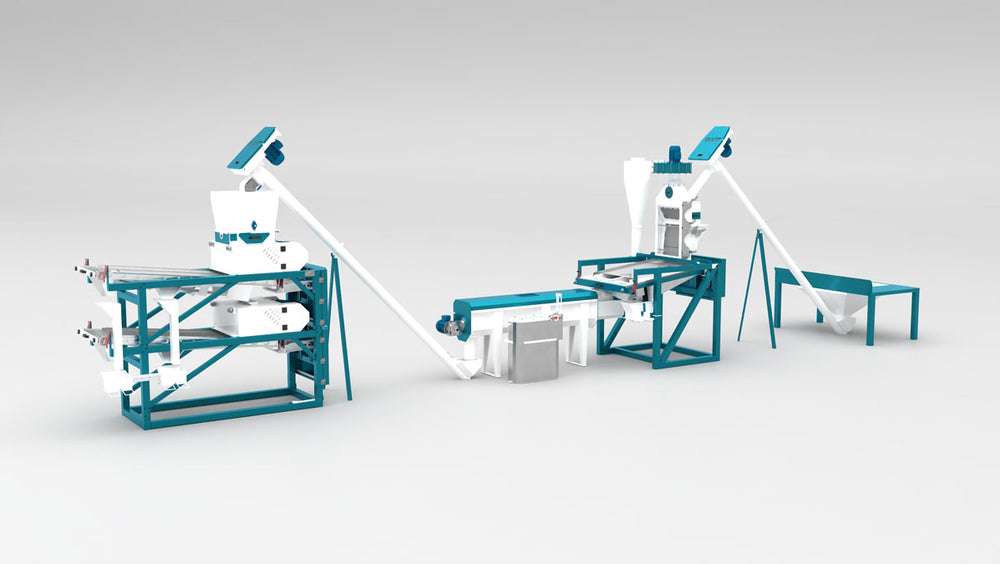

INTRODUCING ROFF’ SP-1 MAIZE MILL

Maize milling entrepreneurs will get more yield with less waste by using the well-priced SP-1 maize mill. Offering you the highest extraction rate at the lowest cost, the SP-1 can produce up to 540 tons of maize per month.

Roff's SP-1 maize mill has everything you need for an affordable business start-up. It is designed to help farmers and entrepreneurs quickly establish themselves in the maize milling industry.

With its simplified milling process, it’s easy to produce high-quality maize meal in four efficient steps.

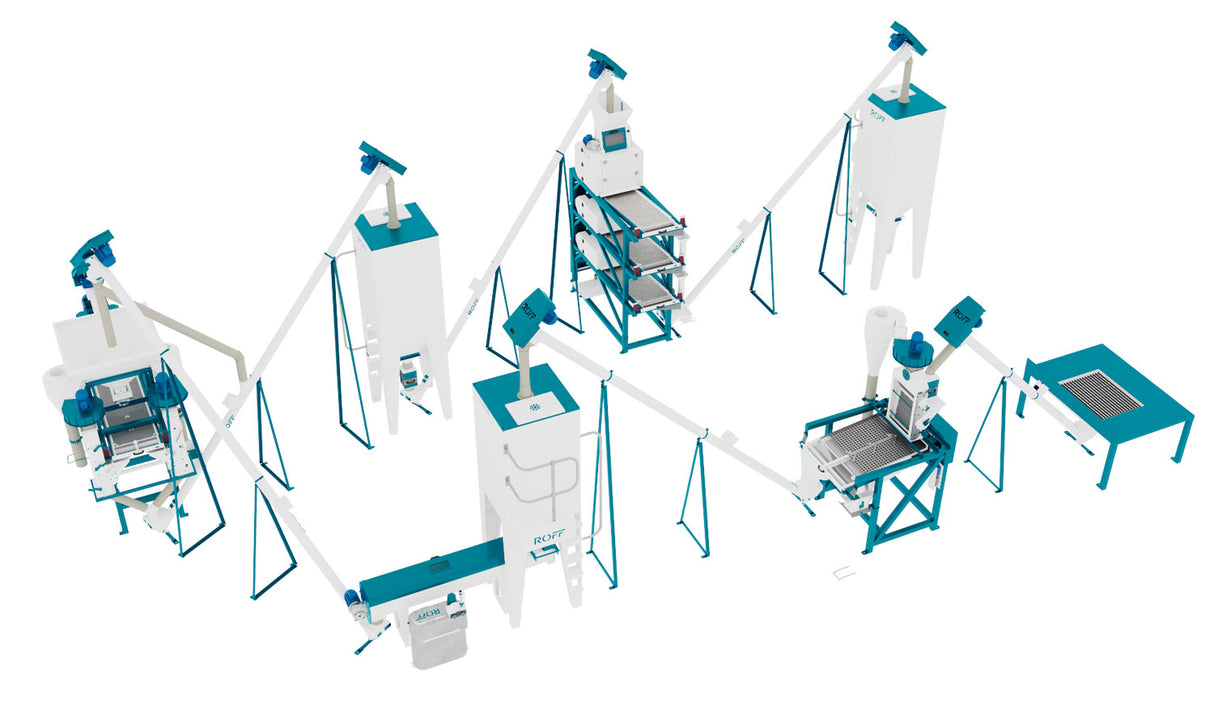

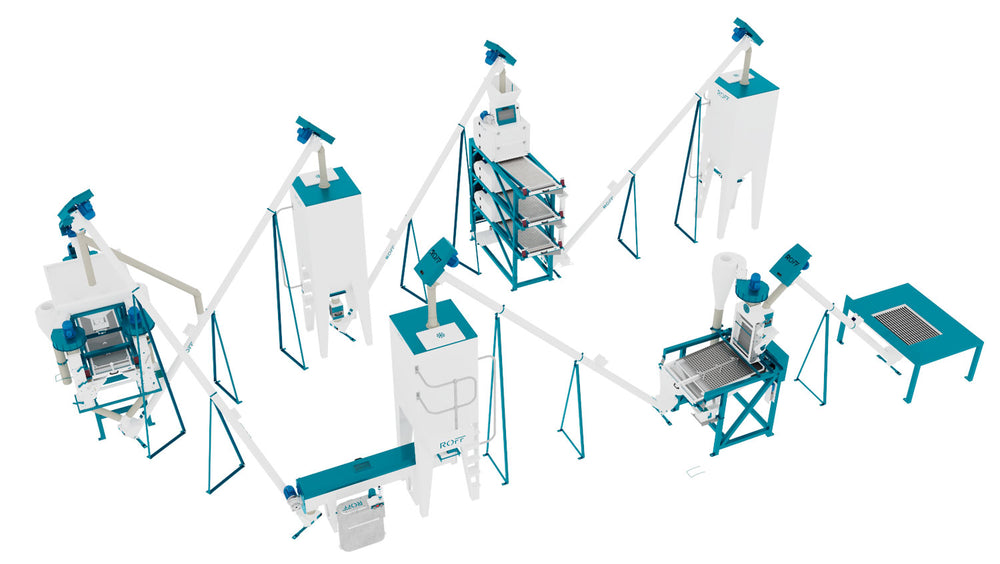

STEP 1: CLEANING

To improve the quality of the final product, cleaning raw maize by removing foreign material such as husk, straw and dust is vital. It also helps to remove substances that are harmful to the milling equipment, such as metal or stones. This process also prolongs the lifespan of your maize mill.

STEP 2: CONDITIONING

Conditioning adds moisture and mass to the maize meal. Controlled humidity increases the effectiveness of degermination and improves maize meal quality. Conditioning combined with a degerminator gives the best results.

STEP 3: DEGERMINATION

Degermination is the removal of bran and germ from the endosperm. It is essential to achieving a more refined product. It also prolongs your end product's shelf-life. The bran by-product from degermination can be sold or used for animal feed, further increasing your profitability.

STEP 4: MILLING

In this final stage, a combination of multistage rollers and integrated screens mill and sieve the maize into a high-quality maize before the packaging process.

All you need to supply in order to operate your Roff SP-1 maize mill is a building, a water point, a forklift for installation, and electrical installation.

1 comment

Hi all,

Does sp 1 come with microfeeder for fortification

Regards