There are two things that millers are responsible for which contribute towards the company making a profit. These are the extraction rate and the milling gain. Let’s look at the importance of maintaining an acceptable extraction rate.

WHAT DOES THE WORD 'EXTRACTION' MEAN?

The maize kernel has three main parts, i.e. endosperm, bran and germ. The endosperm makes up about 84% of the kernel.

The ultimate aim in the milling process is to make the best possible profit margin, without producing finished products of inferior quality.

There are two main methods of calculating the extraction rate; one is used mainly by the miller running the mill on a shift basis, and the other mainly by management on a monthly basis.

QUICK METHODS USED ON A SHIFT BASIS:

Extraction based on total product

This is a quick method used by the miller to calculate his extraction on a two hourly basis and at the end of the shift. He records the net value of each of the different types of finished products manufactured on his shift.

What does the term net value mean? During his shift, the miller might have mixed back into the mill, stock which was either returned by unsatisfied customers, or old stock which had passed its sell-by date. The mass of the products that are mixed back into the mill is deducted from the products that have been produced in the mill. The reason for this is that the mixings were not produced from the maize on the mill, and if not deducted, their mass would inflate the total products milled and give an incorrect extraction percentage. Normally, the meal mix backs are either mixed to special or sifted meals. This rule applies to all forms of extraction calculations.

Another product that is considered a mix back is any screenings from the mill’s intake or cleaning sections. These are mixed into the chop/offal. This applies to this method of extraction calculation only.

The total in kilograms of all of the products produced is divided into each of the individual products net value and a percentage is obtained.

TABLES

Table 1: An example of extraction method:

| Product | Financial Method (kg's) | Millers Method |

| Maize Rice | 7 446 | |

| Maize Grits | 4 525 | |

| Super | 29 400 | |

| Special | 73 860 | |

| Sifted | 2 760 | |

| Screenings | 1 800 | |

| Offal (Including screenings) | 27 042 | |

| Mixings to Special | 1 572 | |

| Clean maize to the mill | 147 001 |

Table 2:

| Product | Gross Mass | Mixings | Net Mass | Extraction % |

| Rise | 7446 | 7446 | 5.25 | |

| Grits | 4525 | 4525 | 3.19 | |

| Super | 29 400 | 29 400 | 20,75 | |

| Special | 73 860 | 1 572 | 72 288 | 51,03 |

| Sifted | 2 760 | 1 800 | 25 242 | 17,83 |

| Sub Total. | 82,17 | |||

| Offal | 27 042 | 1 800 | 25 242 | 17,83 |

| Total | 100,0 |

Extraction based on dirty maize

This method is used to calculate the percentage of products obtained from a quantity of dirty maize as delivered to the mill’s silo, including all of the impurities and before any water (conditioning) has been added. This is used by management, usually on a monthly basis to determine the overall profitability of the mill. (It is not suitable for everyday use by the miller on shift.) The main objective is to calculate all of the products, including screenings in order to see how much product was obtained from the dirty maize purchased.

The quantity of dirty maize milled is calculated as follows:

Opening stock at the beginning of the month.

Plus

Maize deliveries received during month.

Sub Total

Minus

Closing stock at the end of the month

Equals

Maize milled for the month.

Note: The DM figure obtained is then divided into the net mass of each of the products made on the mill. (The screenings produced in the silo/screenroom must also be divided by the monthly maize milled figure.)

EVAPORATIVE LOSS

It is usual practice when the miller calculates his extraction on the mill, to include the calculation for evaporative loss.

What is meant by evaporative loss? This is the difference in mass between the quantity of maize milled and the total net mass of the products produced from it. Under normal conditions this should not be more than 0,5 to 1,0%. The evaporative loss is caused by the following:

- The pneumatic system in the mill.

- Heat generated by grinding on the roller mills.

- Chokes in the mill that have not been picked up and mixed back.

- Packing of over mass products or faulty/inaccurate mass meters (scales).

- Not deducting any of the returned product (mix backs) into the mill. (This would result in an evaporate gain).

- Some of the above, such as the first two items, are not always under the control of the miller, but most of the others are.

There is another factor involved which is the invisible loss. This may be defined as that part of the evaporative loss which cannot be accounted for. It may be caused by the loss of product through faulty filter, chokes that cannot be mixed back because they are contaminated with e.g. oil.

It is the miller’s duty to ensure that the above losses are kept to a minimum.

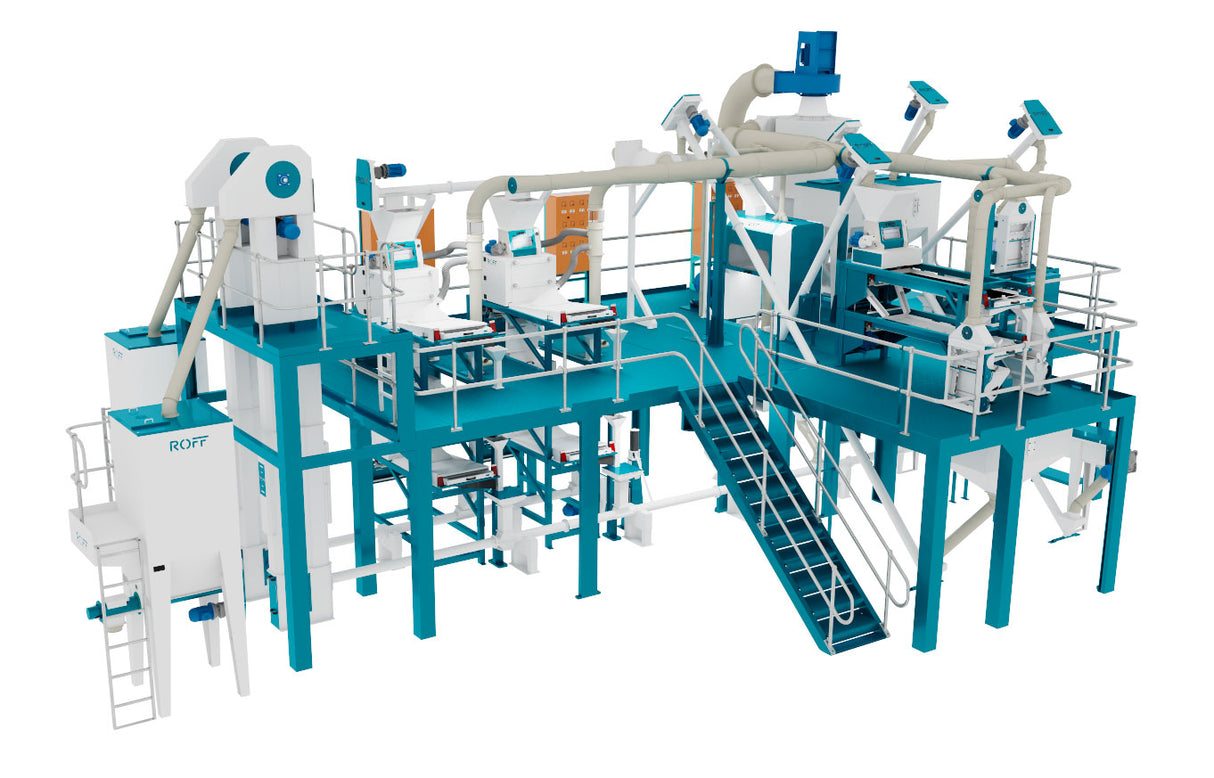

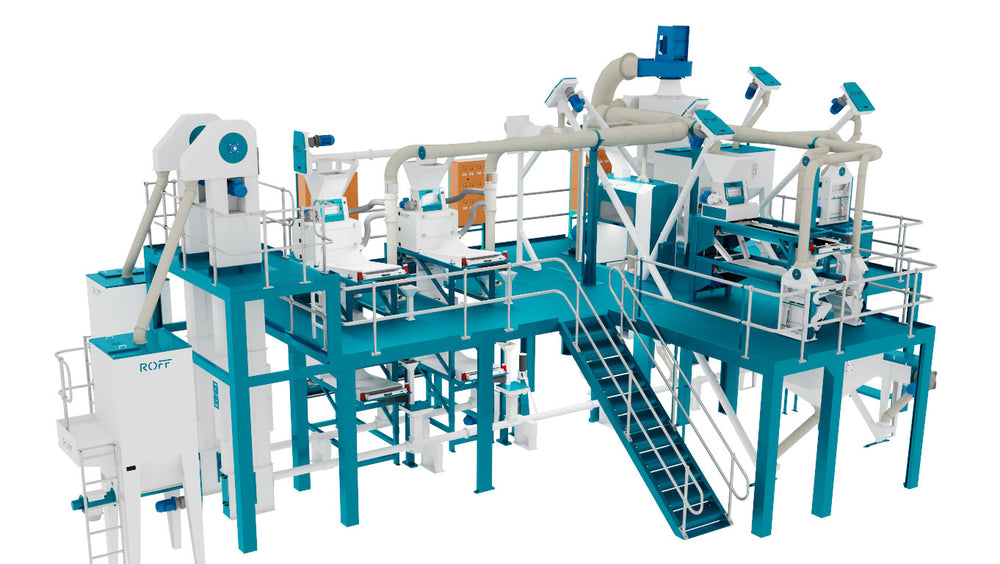

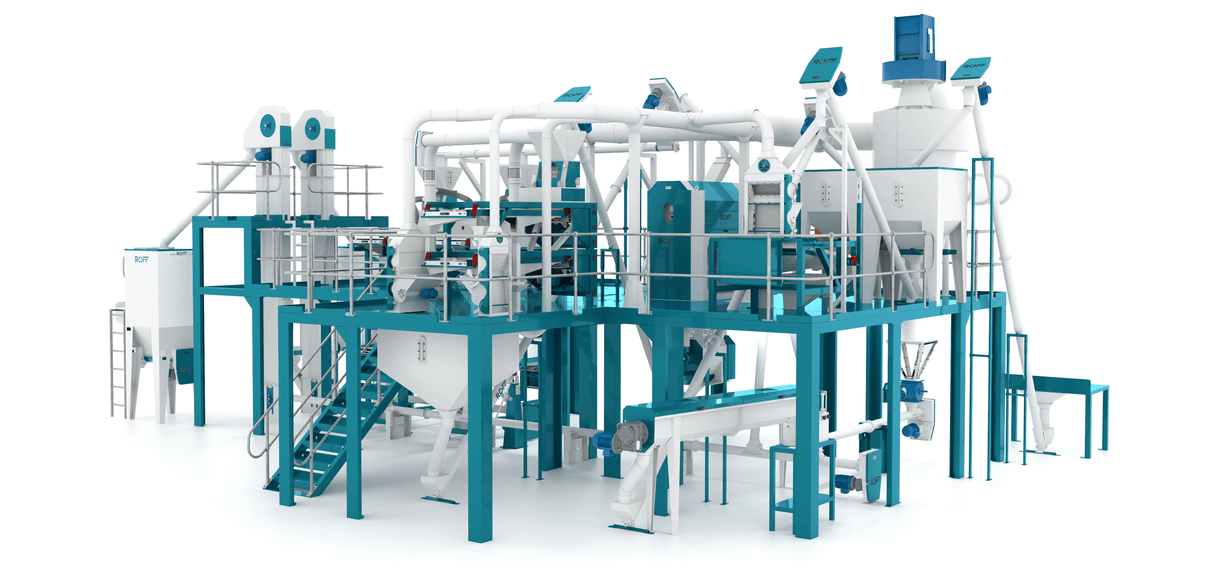

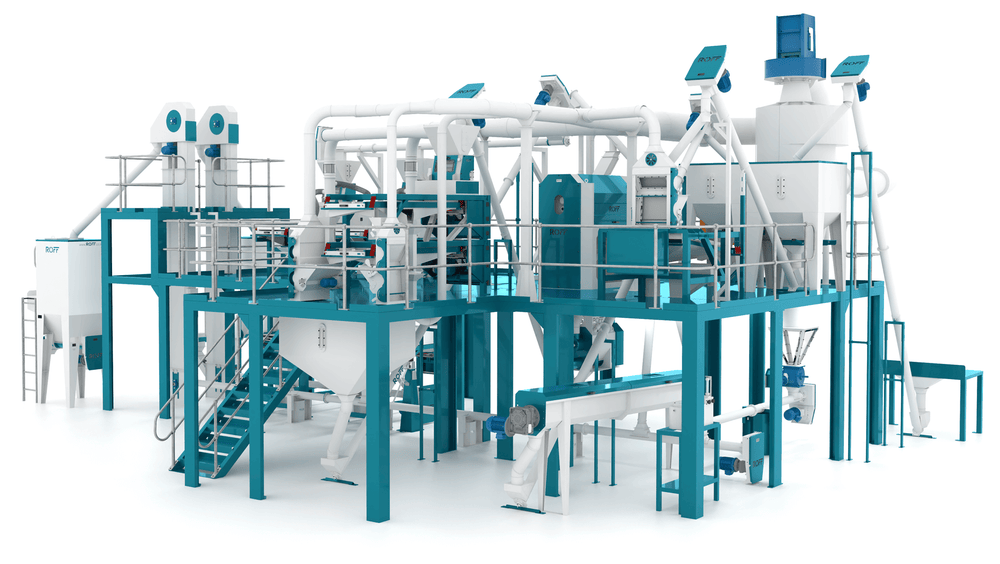

GET THE BEST EXTRACTION RATE WITH A ROFF MILL

Roff’s high-quality maize milling machines are designed to deliver best-in-class extraction rates. This in turn will give you, the maize milling entrepreneur, the best possible chance at profitability so that you can grow your business. Get in touch with Roff Milling today for advice on buying the right milling machine for your operation. Call us on 27 56 212 2697 or email sales@roff.co.za

3 comments

I always review you page and I get more important hints so it some how advantage to me

Which maize to use to produce the best product

how do you calculate the amount of water to add for conditioning ?