The maize milling value chain indicates the relationships between different market players within the supply channels.

As a community or commercial maize miller, it’s important that you understand the processes and primary players in the maize industry, along with their position in the value chain so that you can decide where your operations might slot in.

What is a value chain?

According to Investopedia, a value chain is a series of consecutive steps that go into the creation of a finished product, from its initial design to its arrival at a customer’s door. The chain identifies each step in the process at which value is added, including the sourcing, manufacturing and marketing stages of its production.

The end goal of a value chain is to create a competitive advantage for a company or industry by increasing productivity while keeping costs reasonable.

Maize milling value chain in Africa

Here is an outline of the maize milling value chain in Africa pertaining to community and commercial millers:

Inputs and maize production

Maize is a key crop in many African countries, and is grown by both smallholder farmers and commercial farmers.

Inputs that feed into the maize milling value chain include research and development (R&D), land, water, seeds, fertiliser, pesticides, machines and labour.

The quality and of maize produced impact the milling process and profitability. For instance, if maize is degerminated as part of the milling process, maize sourced from low rainfall areas without irrigation will ensure higher extraction rates.

Maize transportation and storage

After harvesting, maize needs to be transported to storage facilities which can include local storage, collection centres or warehouses. Since transport adds such significant costs to the maize production process, maize producers usually aim to supply maize to their nearest silos and/or local storage facilities to save costs. Millers also try to operate as close to their maize source as possible to keep their raw material transport costs as low as they can.

This explains why in South Africa, for example, the biggest maize mills are located close to maize production areas in the country, and none for example in areas like the Western Cape. It’s more economical to transport an expensive product over longer distances than raw materials.

Therefore, it makes sense to mill as close to your maize source as possible and rather transport your product over longer distances.

The correct storage is vital to ensure that maize does not spoil or get contaminated. Players in this step may include village agents, traders and wholesalers.

Maize cleaning and milling

Before milling, the maize needs to be cleaned to remove impurities such as dirt, rocks and broken kernels. This is done using machines like grain cleaners or air aspirators.

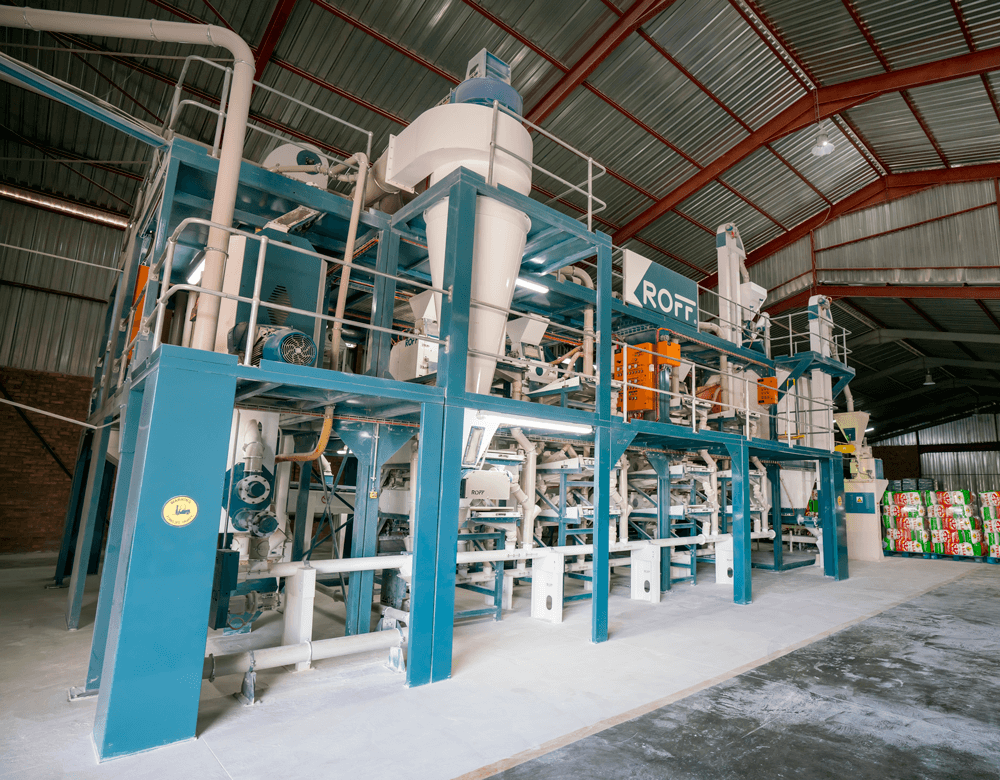

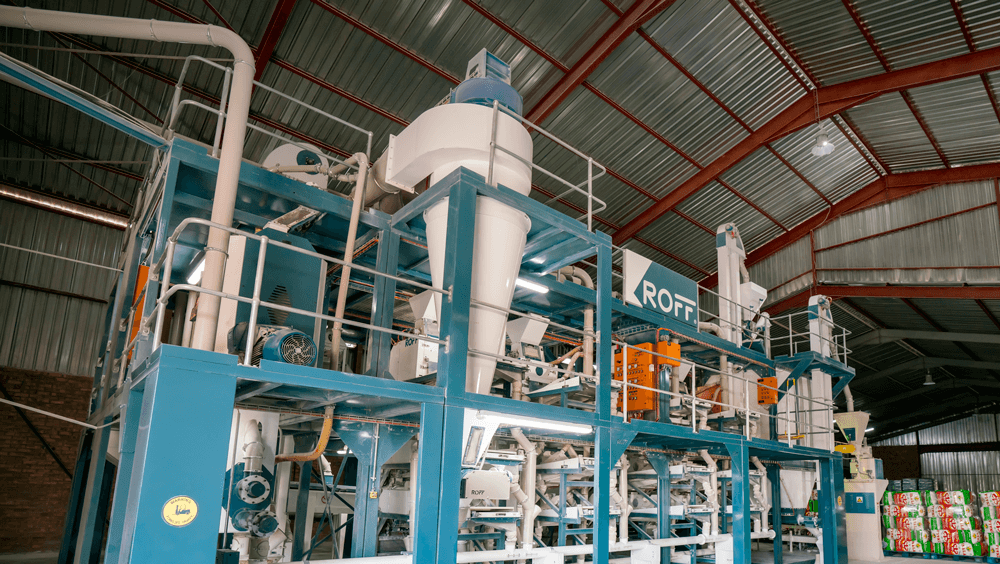

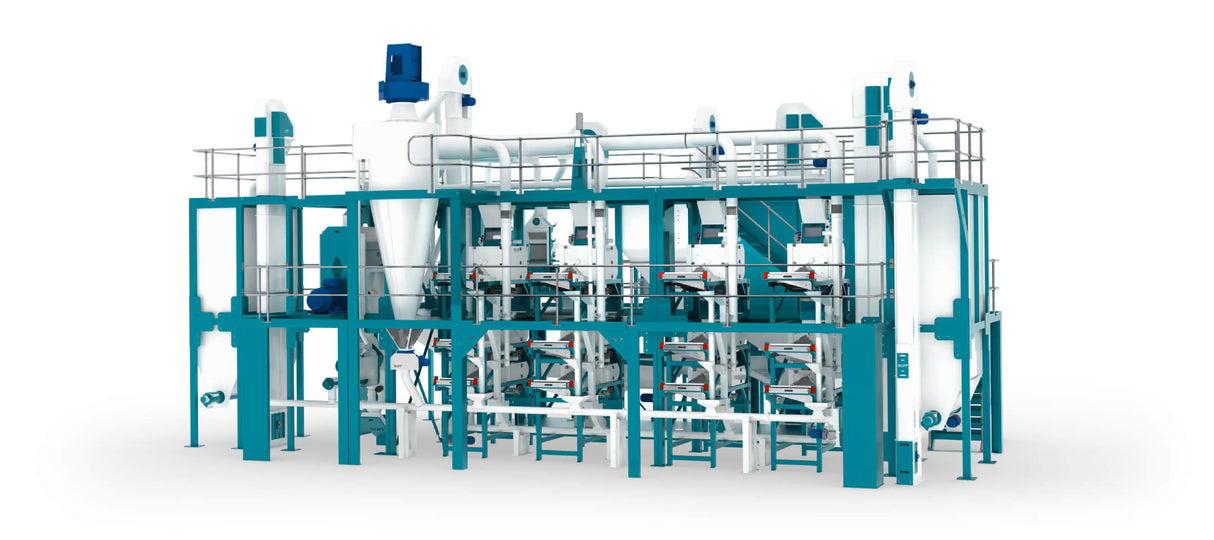

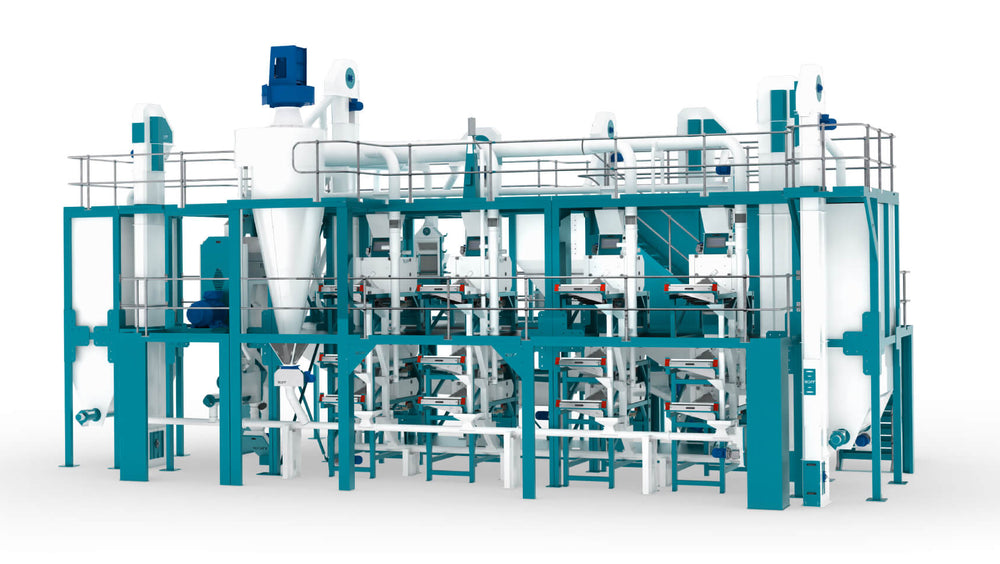

Maize is then milled into different products such as maize meal, maize flour and maize grits. The milling process involves several stages, including dehulling, milling, sifting and packaging. Commercial maize millers use large-scale milling equipment, while community millers use more cost-effective, simpler equipment that takes up less space and is energy efficient.

Waste/by-product management

Finally, the maize milling value chain generates waste products, for example maize bran and maize germ. These by-products can be used for animal feed or other purposes.

Packaging and distribution

Maize products are packaged into different sizes and sold to different markets. Commercial maize millers may sell to wholesalers, retailers or directly to consumers, while community millers may sell to local markets or directly to consumers.

Consumption

Maize products are consumed as a staple food in many African countries and used to make dishes such as porridge, bread, other baked goods and drinks.

In conclusion

The maize milling value chain is important for both commercial and community maize millers in African maize producing countries. The quality and efficiency of the value chain can impact the quality and availability of maize products, which are crucial for food security and livelihoods in many African communities.

Sources

4 comments

Very good information, thanks for sharing

I am request your Email Address

1. want to know where you are situated

2. I want a lot of maize meal

———

Roff Milling replied:

Hello Moses, Roff is a maize mill manufacturer, we are situated in Kroonstad, Freestate, South Africa. You can contact us at sales@roff.co.za<mailto:sales@roff.co.za>. Regards

Thanks for sharing your wealth of knowledge. Looking forward to working with you.

———

Roff Milling replied:

Hello David, if you have any further questions, please do not hesitate to contact us.

You are doing great and keep it up! I will be your potential customer soon as I collect funds

Dotto from Dar es Salaam Tanzania

———

Roff Milling replied:

Hello Dotto, thank you, we look forward to it.