Retailers are crying out for high quality and affordable maize meal, the staple food of most African populations. But due to drought, economic instability and price fluctuations, the potential to produce enough maize meal every year is compromised. This shortfall means smaller maize milling entrepreneurs and farmers have an opportunity to augment the demand for maize meal. However, investing in the maize milling industry still needs to be sound and cost-effective to maximise production and profit.

To invest with confidence, maize millers need a mill that's easy to maintain and operate, but most importantly, produces high-quality maize meal. Roff's R-70 ticks all these boxes and is the number one choice for any entrepreneur looking to successfully break into the industry and maximise their profitability in the maize milling industry.

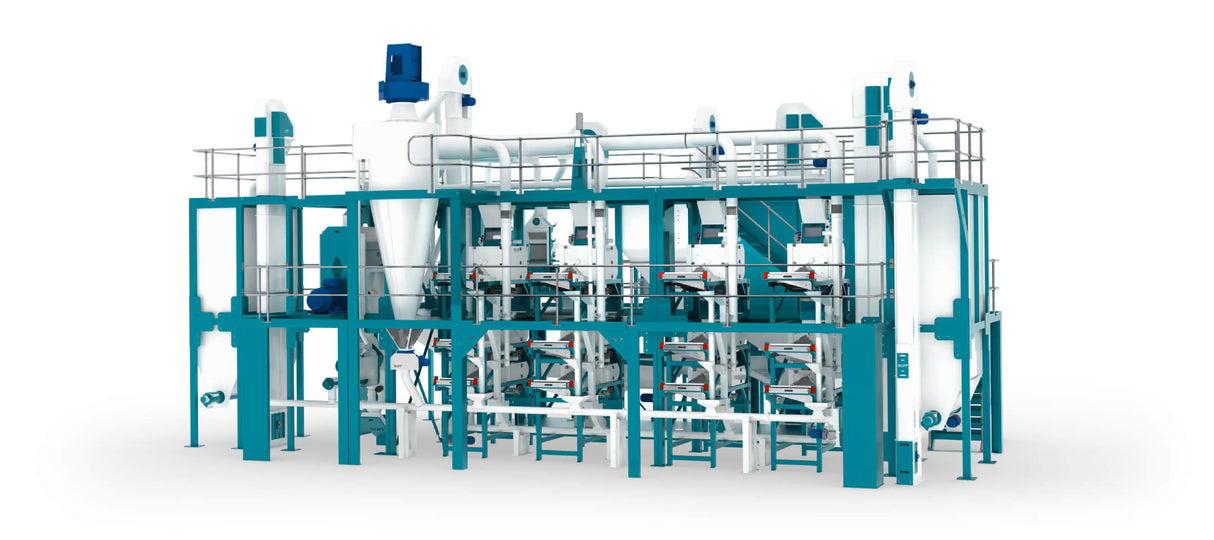

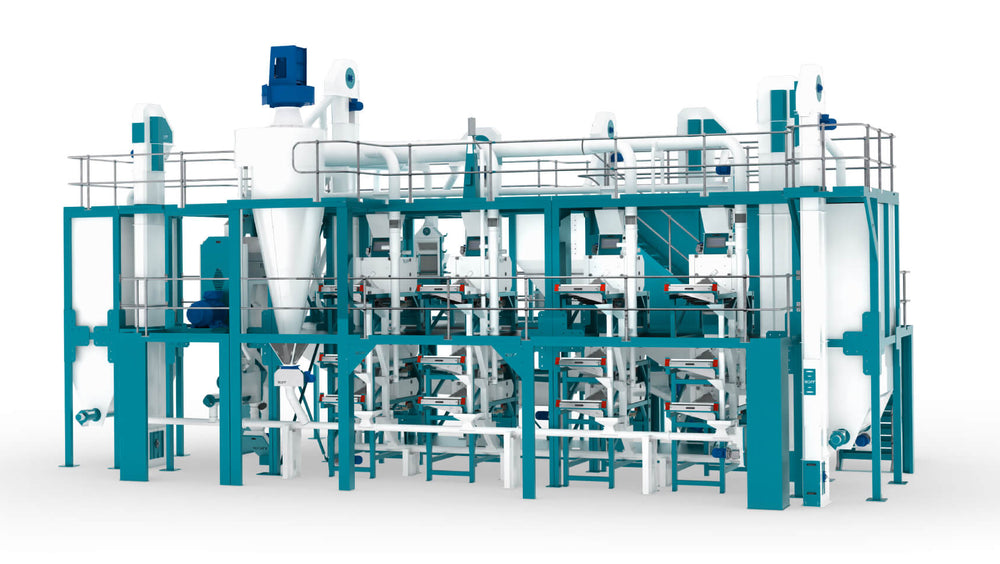

In maize milling, your profit margin is directly proportional to maize meal extraction rates. The R-70 milling machine is renowned for its above-industry average extraction rate. Capable of up to 100 tons a day, at 85% high-quality maize meal, the R-70 easily surpasses standard production capacity. And with the 'bran/chop' leftover, to be used as animal feed or sold.

The R-70 was developed for entrepreneurs looking for a cost-effective way to break into the maize milling industry or established maize farmers to improve productivity and quality of maize meal. The R-70 is a compact mill that enables the client to mill 50 to 100 tons per day, producing super or special maize meal depending on the configuration.

Johann Vos, a Roff client, switched to the R-70 mill five years ago said, "As they say, 'Your dreams have to scare you. Otherwise, they are too small.' When we put up the first 1500-ton silo, I didn't know if we could fill it. But, two months later, we were forced to put up a second one."

To maximise a mill's earning potential, you need to be able to produce year-round. "You can't supply only after harvesting season because you have standing customers. You have to get a foot in the door as you are competing against major players in the market," says Vos.

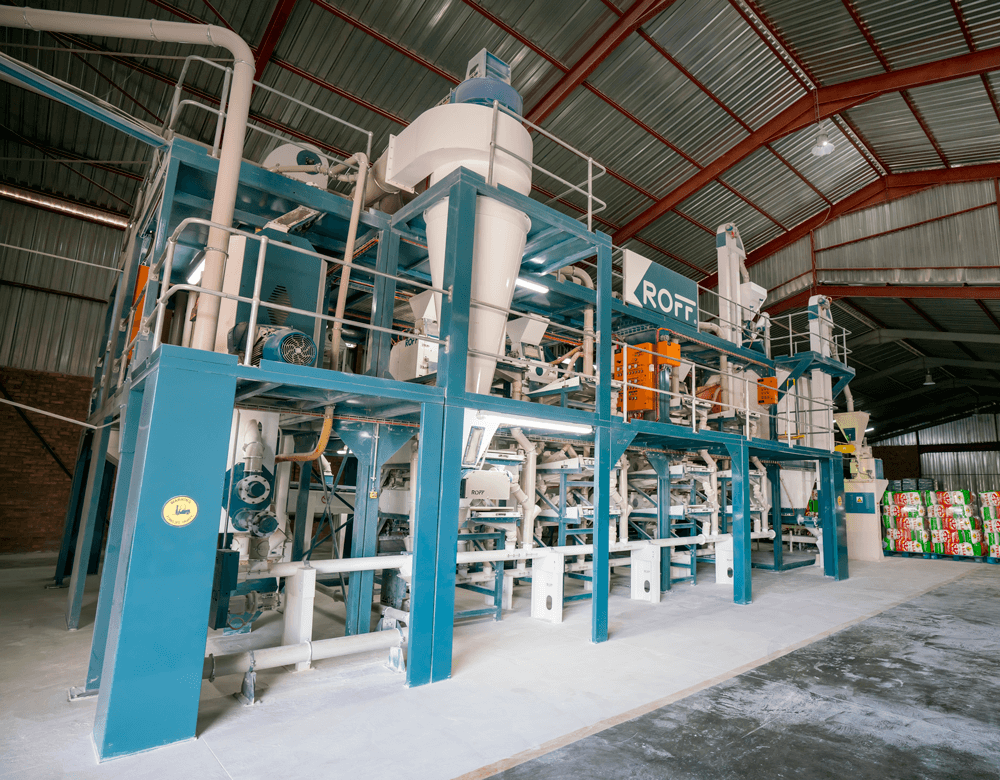

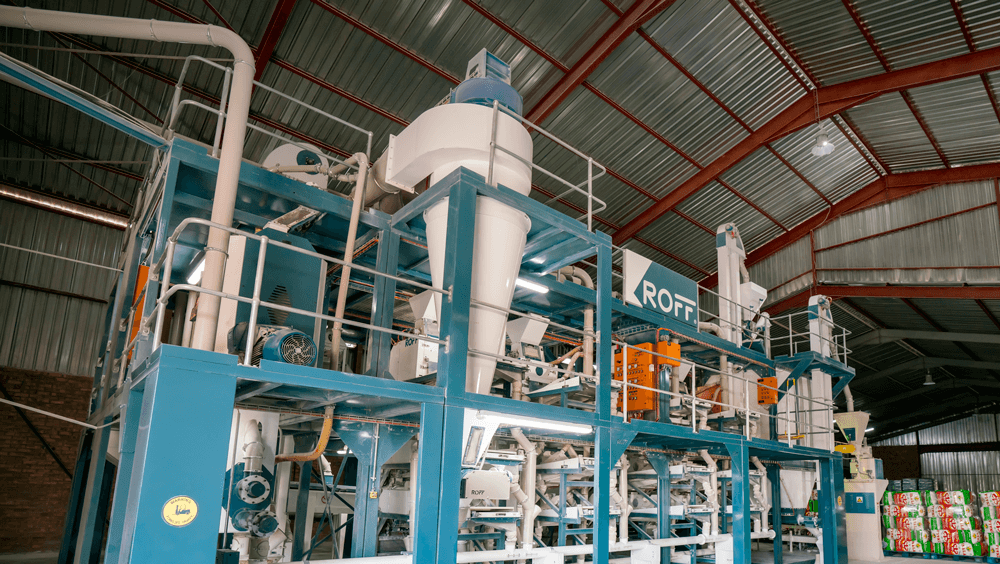

With the tried and tested reliable R-70, it's possible to mill maize year-round. The R-70 efficiently takes care of the entire maize milling processes from cleaning to the final product. The R-70 comes standard with a surge bin for maize inlet, cleaning and conditioning equipment (with a conditioning bin), milling, degermination, sifting, conveyors, electrical panel, electrical cabling and all steel structures. In some regions a less refined quality is preferred, so the degermination module and extra conditioning can be removed. All you need to provide is a suitably sized building and water and electricity supply.

Maintaining a mill can cost up to 10% of your capital outlay, upkeep of the milling machine needs to be easy and cost-effective. The R-70 has two levels, so all critical points are easily accessible, allowing the miller to view and access components. Plus, all stages are ventilated, preventing condensation and dust build-up - allowing for a low dust process.

Roff designs and manufactures maize milling machines that empower farmers to produce high quantities of high-quality maize meal to meet retailers and consumers demands.

In short Roff's R-70 helps farmers mill maize into profit.