Roller mills have been used since the 17th century. First made of stone, their effective concept of crushing grain through sets of cylindrical rollers has stood the test of time. With the advancement of technology, the same principles are still applied to modern roller milling machines today.

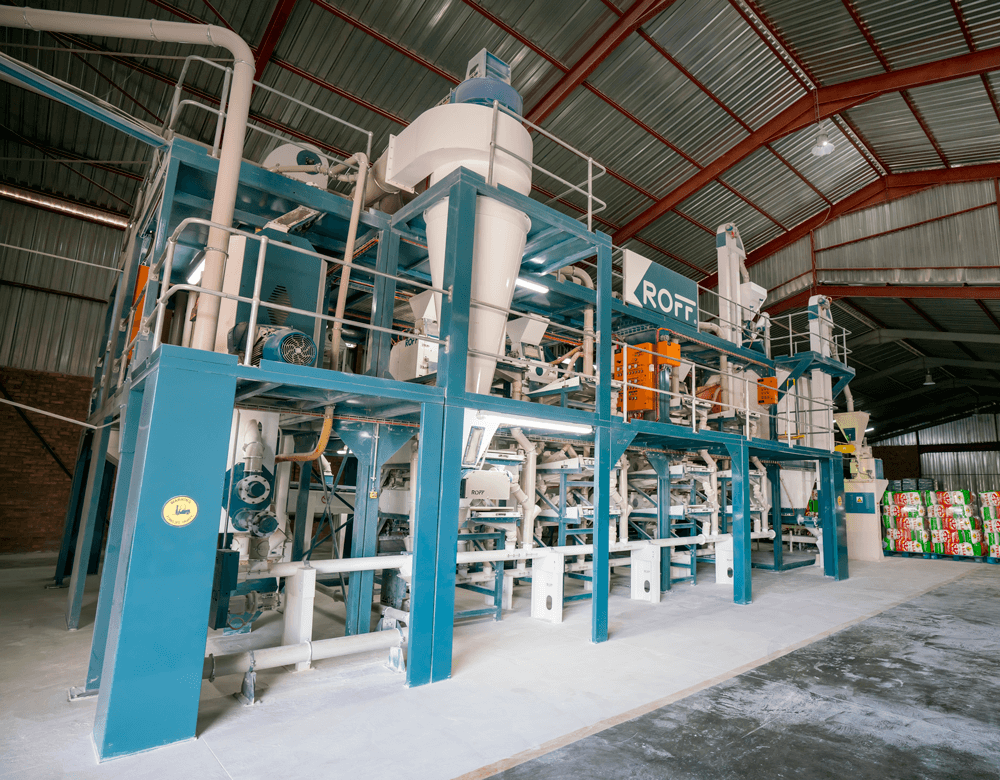

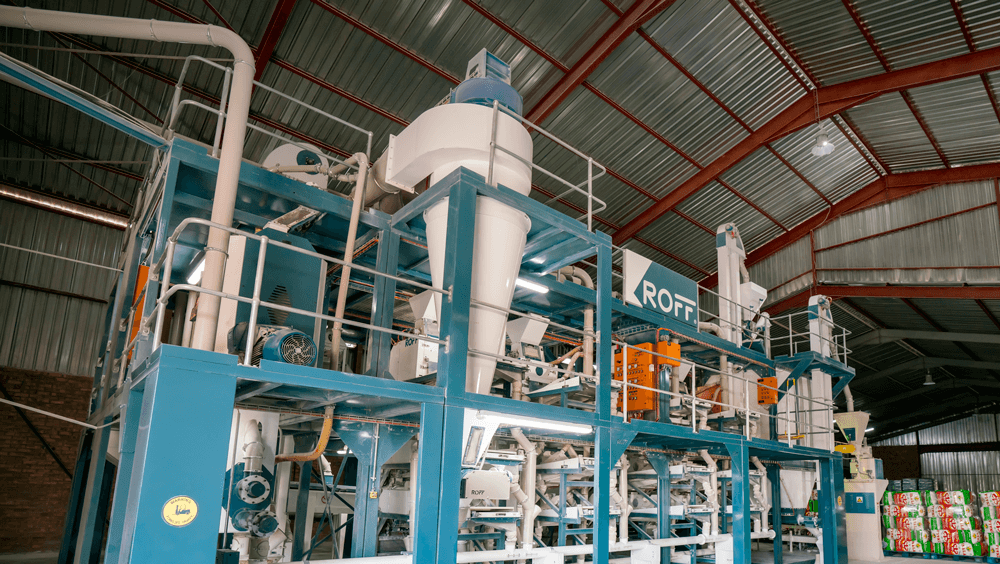

After 25 years as the leading manufacturer in maize milling equipment, we at Roff have taken the concept of roller mills to even greater heights. By implementing the proven MK6D rollers in the heart of our compact R-70 maize milling plant, we have achieved the best results possible.

Building simple, high-quality machines have always been Roff's goal. The R-70 mill, which has been developed for the entrepreneur who is looking for a cost-effective milling process, is no exception.

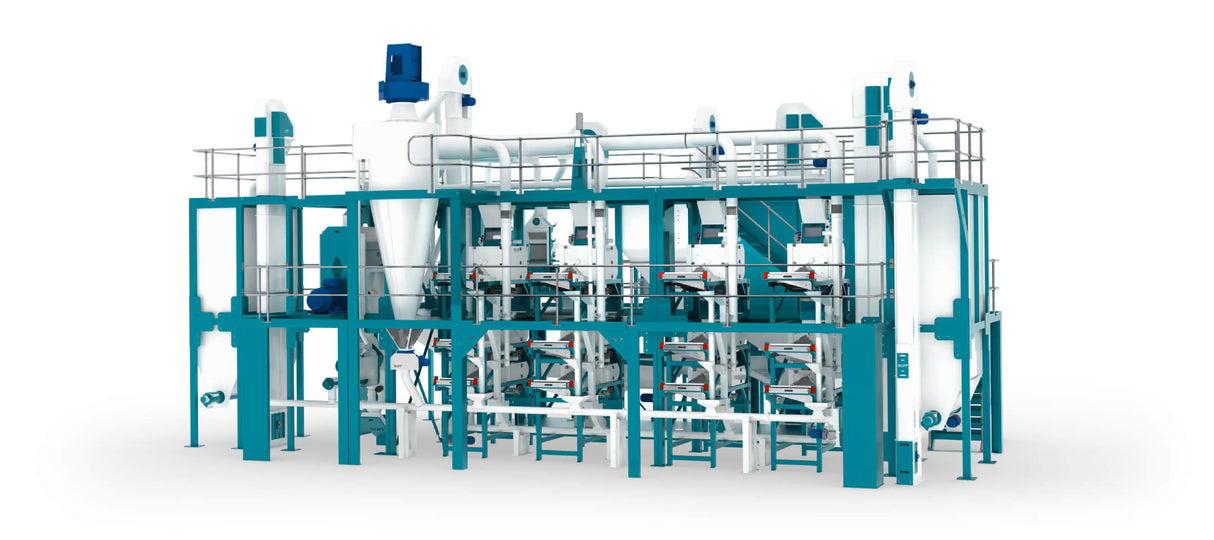

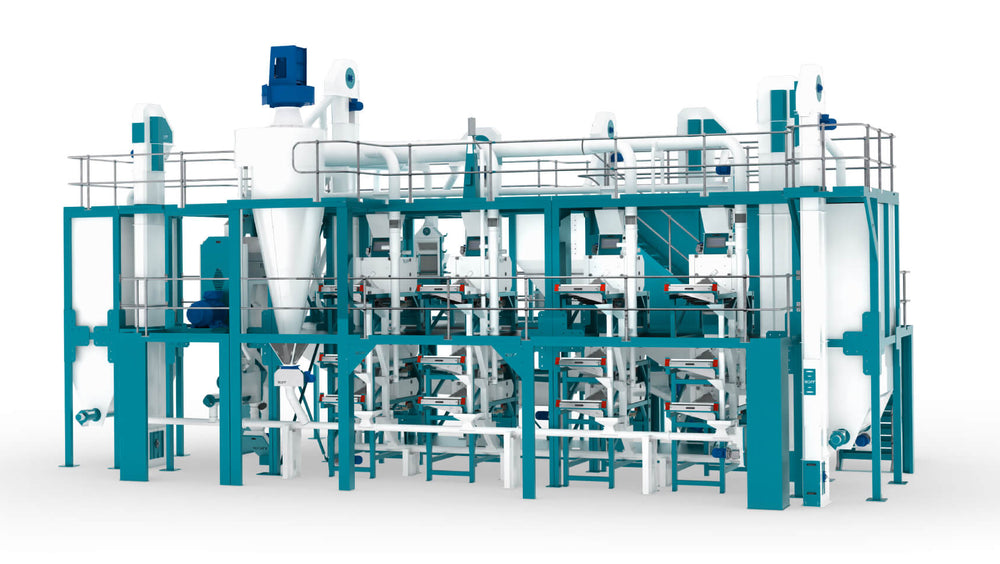

With the installation of the MK6D roller mills into the R-70, producing a high-quality product at profitable extraction rates is made simple. The MK6 is a unique three-stage combination of rollers and screens. Each stage allows full control over the flow of your product and the incorrectly sized product is milled and screened again, ensuring the maximum possible end product is extracted, using gravity without the need for extra conveying and sifting equipment.

Top reasons why Roff has implemented MK6D roller mills into the R-70 milling plant:

- By combining milling and sifting into a single machine, the milling process is shortened and made more affordable.

- A smaller structure is required for the mill as the combined milling and sifting process takes up less vertical space, and only uses gravity to feed the next stage.

- The MK6D roller mills are easy to maintain and operate with no specialised training required.

- They produce a high-quality product at above-average extraction rates.

The R-70 maize mill is an all-in-one milling solution for anyone looking to start out in the maize milling industry. Not only is it compact and user-friendly, but it also allows you to grow your business without limitations. Depending on the configuration you set it to, the R-70 can mill 50 or 100 tons a day, making it an adaptable and profitable asset to your milling business.

Installed over only two levels on the included structure, all critical points of the R-70 are easily accessible so that the operator can easily monitor all processes as well as keep the unit well-maintained. Compact and easily installed, all you need to provide to obtain your R-70 roller mill is the location, water and electrical supply.

Read more about this competitively priced, top-quality milling machine here.

2 comments

Kindly provide me with the price for your 1tph or 1tpd Roff Mill in US dollar

———

Roff Milling replied:

Hello Esther, our sales team will get in touch to assist. Kind Regards

Hello sir

Please provide me with the price for complete Maize milling Machine for 20T/24

And 30T/24 Hour

2. The measurements required to accommodate both types of machines

3. Shipping cost to Mombasa Kenya

4. Service after installion