Every industry has certain risks that have to be managed in order for the business to succeed and be profitable. In this blog, Charl Marais, Managing Director: Roff Milling, shares important risk management considerations for every maize miller. Let’s take a look.

01. Profitability

Many business owners do try to manage a variety of risks, but then neglect to ensure that their business processes are profitable. It’s important to get the basics right, like following sound business principles, efficiently managing debtors to ensure that the money comes in, and making sure the relevant legal processes are in place.

Let’s say a 35-ton load of maize meal is worth R200 000. If the miller were to deliver 2 or 3 loads to his customer without having the assurances in place that the customer can and will pay for it, that’s a risk the miller is taking that can easily backfire. What did the miller do to manage his risk?

It’s therefore key to be certain that your customers are in a position to pay you when they should. In Roff’s case, the business has in the past had to close accounts of big JSE listed clients because they were bad payers. Remember: A customer is someone who pays you in return for a service rendered or a product offered. The payment part is kind of important!

Another important aspect related to profitability is optimising your technical processes. You have to deliver good quality maize meal at good extraction rates. As such, you have to measure your extractions, or else you will not know whether you are winning or losing*. At the end of the day, the miller has to find a balance between delivering a product that the customer is happy with, and that makes a profit for you.

02. Electricity

Needless to say, loadshedding results in a lot of wastage, from the mill stopping and starting, to product changes that mean the maize meal has to be discarded, etc. When the miller stops the process, he stops the input streams and as a result, the output stream quality starts changing. When it gets to a point where the product is no longer acceptable, the miller then has to switch over the diverters to wastage, let the machine run until empty and get rid of all the product. Milling is a low margin, high volume business, so if you lose loads during every loadshedding turn, it adds up quickly.

Loadshedding really hurts the bigger maize millers players too. This is due to the fact that they don’t get their volumes out, a loss of production hours due to load shedding, and a loss of production hours due to the stop/start of process. In a big process, the head miller has to be present whenever the process stops and starts. So during load shedding, it means they are needed constantly. Then we’re not even talking about how electricity outages affect ongoing processes like conditioning: so now a products lies in the conditioning bin four hours longer or shorter. The miller doesn’t want a variation in time or moisture. Whatever you do, just stay consistent with the product you offer.

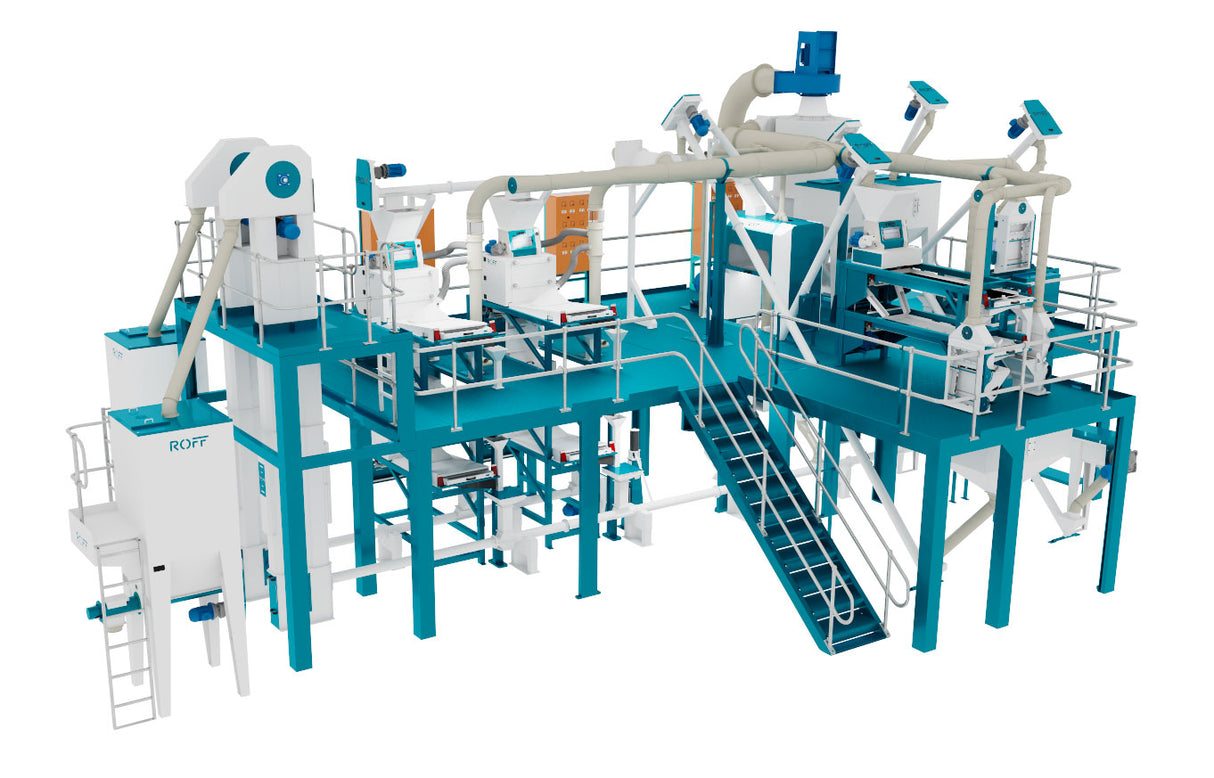

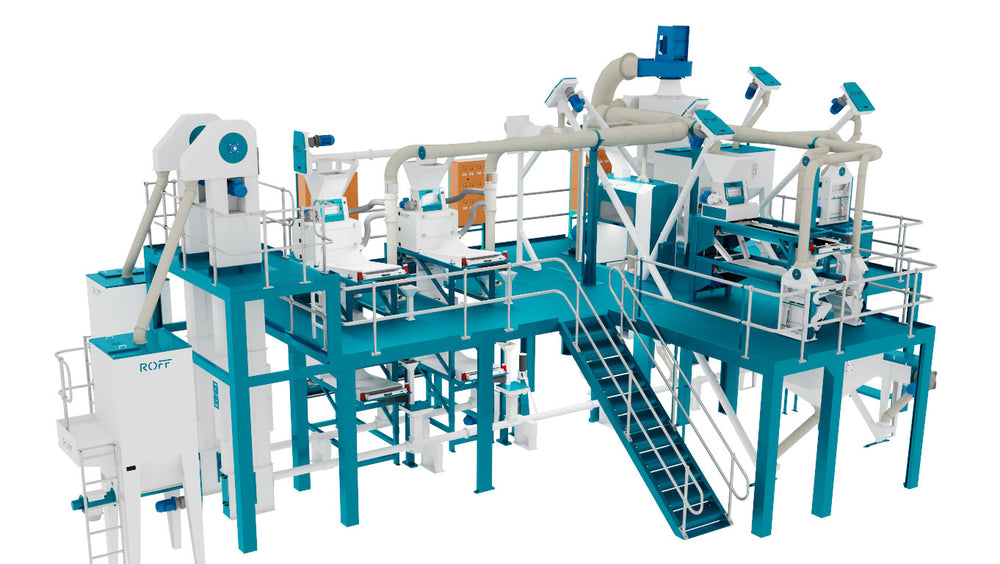

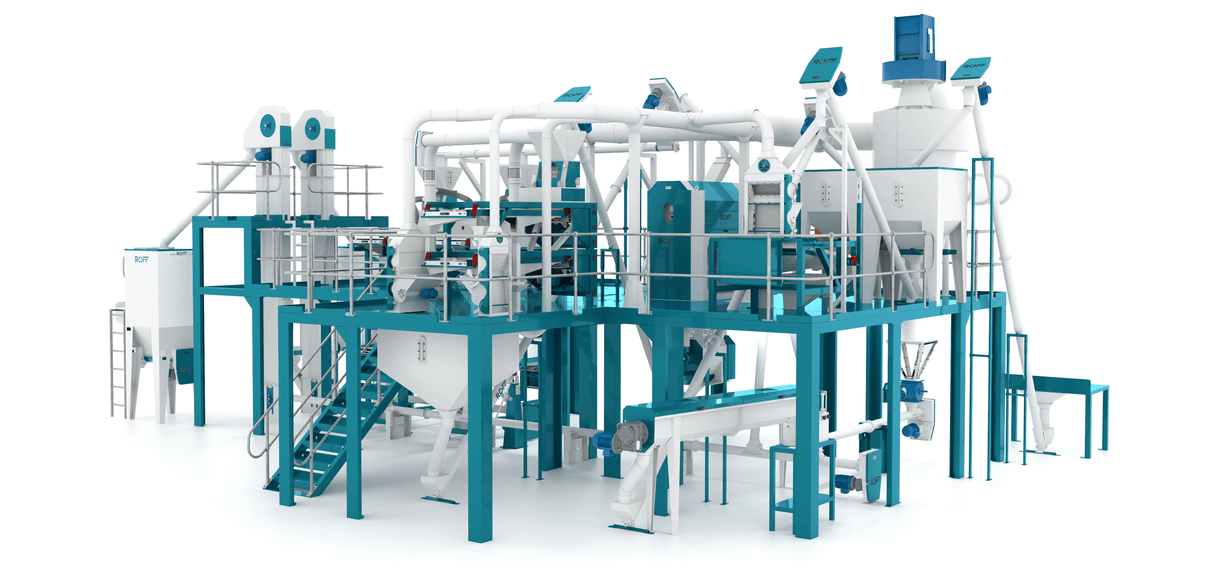

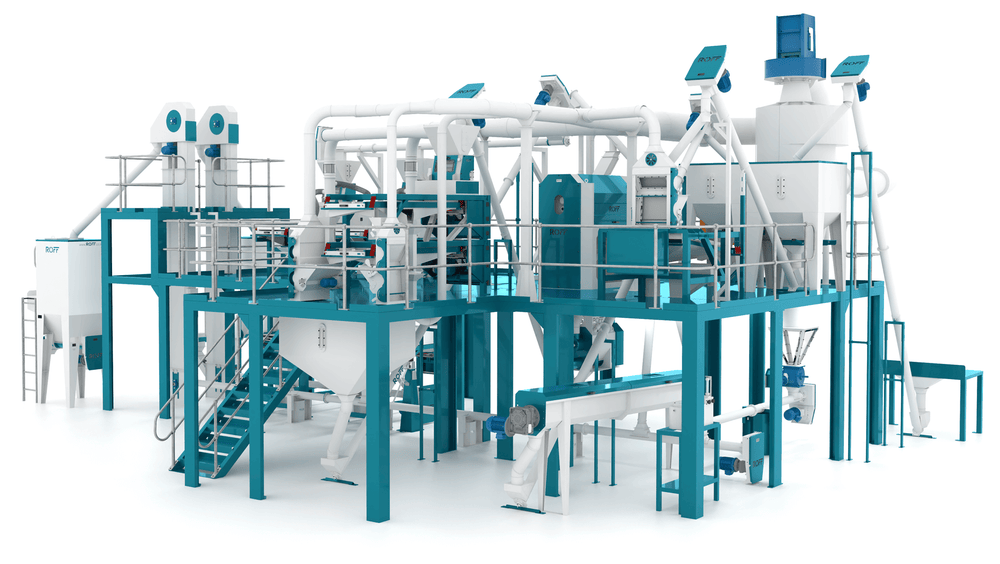

Roff mills are designed to keep productivity up when loadshedding lets you down

While electricity supply is a very real risk, Roff mills are designed with simplicity in mind so it’s not such a big risk for Roff clients. The miller simply switches off a Roff mill and starts it. For example, it the miller switches off a Roff R-70 maize mill, he doesn’t even have to throw out the meal to the wastage bin, because the streams are short and very consistent. This provides a huge advantage to Roff clients.

We are also looking to move the Roff C-80 away from a programmable logic controller (PLC) – because there is a skills shortage, and fluctuations in electricity break the electronics. Contactors can handle these fluctuations, but the first things to go are the motors.

* Roff is also in the process of developing a process weigher that will help the miller ascertain his extraction rates. More information will follow soon.

03. Raw materials

The procurement process of raw maize remains a risk, in particular, hedging against prices that can vary significantly. It’s always beneficial when you as the miller don’t have stock and prices decrease. But just a year or two ago for example, prices rose drastically, which can be fatal to a small miller. A larger mill with better procurement processes will however have stock, so an increase in prices is not that big a deal. Having stock doesn’t have to mean the maize is lying in a silo, but that the miller has signed contracts in place throughout the season.

Three months before harvesting season, you will have a good indication of what the price is going to be. We advise that millers have a third of their usage in contracts in place a quarter before harvesting. In South Africa, companies like Senwes Grainlink and Grain Traders have good tools in place to help millers do that.

In business, entrepreneurs and business owners should plan and be prepared for the risks posed by their industry. With a 30-year track record in maize milling, Roff Milling will partner with you to help you navigate the risks and achieve success.

2 comments

Thanks alot, iam very greatful for the information shared. God bless u.

Very insightful article, keep up the good job.