Load shedding has become an ever-present reality in Sub-Saharan Africa. Apart from causing great inconvenience to everyday life, it has a significant impact on the region's GDP, on the manufacturing industry in particular. Some South African economists estimate that stage 6 load shedding may cost the country a staggering R4 billion per day.

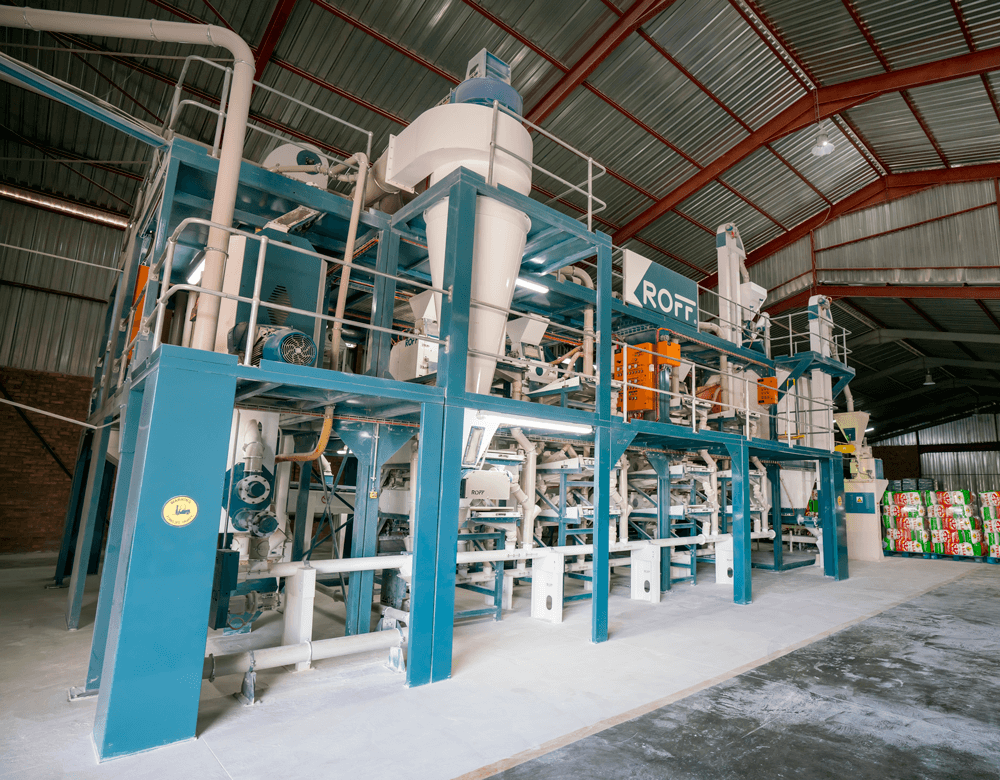

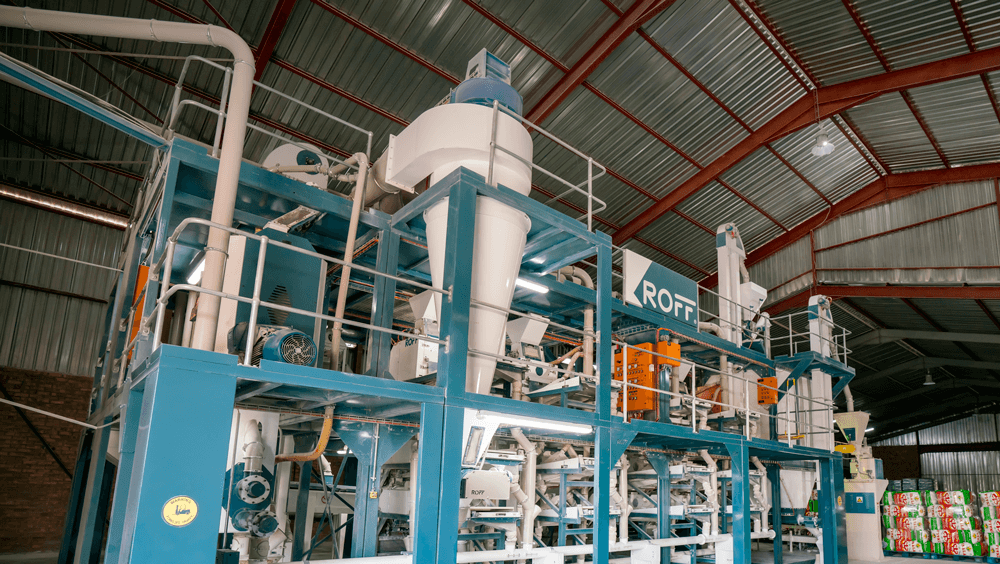

To mitigate the risks associated with regular load shedding as a manufacturing company, Roff has invested in a state-of-the-art solar system for its manufacturing plant in Kroonstad, Free State, South Africa. In addition, the company looks forward to a big reduction in electricity costs and lowering its carbon footprint.

This blog offers a few insights Roff gathered along its solar journey, which might be of use to maize millers also considering going the solar route.

Why did Roff invest in a solar system?

Roff invested in a solar system for two main reasons:

- Firstly because it makes financial sense. The bigger your investment in a solar system, i.e. the more kilowatt you can self-generate, the bigger your return on investment as your cost per kilowatt becomes lower. Solar is a relatively good investment.

- The second reason is risk management. Ask yourself: what’s the true cost to your business when you don’t have electricity for extended periods of time?

Roff installed a 120kW system. The new solar panels use about 5.5m2 per Kilowatt hour. Fortunately, Roff had enough roof space for this installation, with room to spare so we can add an additional 50kW in future.

REASON 1: Financial motivation

Roff obtained five quotes from different suppliers based on our business needs. All suppliers based their sales pitches on the financial model i.e. the fact that a solar system could save the business money, but you also need to consider the following:

- Could the capacity of the system be increased later, and to which extent? Will you outgrow it in the next few years?

- Does it allow you to monitor the system and make changes as needed, either with a PC connection or mobile app?

- Will the hardware last?

- Is the hardware from a reliable brand that will be able to support you for the lifespan of the product and beyond?

Consider where the PV panels are going to be installed:

If you consider a roof installation, ensure that the roof structure can handle the weight of the installation by consulting a civil engineer. You will also need an engineering certificate after the roof installation. PV panels can also be installed as a ground installation that can be easily cleaned and maintained, e.g. in a carpark.

Measure your usage first

But first things first: You need a device called an energy logger that measures your usage before you install a solar system. Install this equipment, which can be hired, for a month so you can see exactly how much electricity you use. It’s worth it, because without this data you won’t have an idea of what your actual usage is. This will help you get it right the first time – especially in the context of a mill or a large industrial setting. Roff’s peak usage was measured at about 170kW.

Deciding on the system you need

If you think of the usage as a graph, about 80% of your general electricity usage would lie in a straight, consistent line. E.g. think of switching on your oven at home – it draws the same amount of power most of the time. However, to switch on the oven and get it to temperature will initially form a big peak.

These peaks are quite a challenge to work with when designing your solar system. When taking cost-effectiveness into account, you obviously want to stay below the 80% line section of your graph, add solar panels and harvest 120kW (80%) from the sun and add it to the system. In this straight section of your usage, you will use most of the electricity that you generate. The challenge lies in the fact that when your equipment is starting up, it initially forms big peaks at different times before returning to the base line. As such you have to design for the biggest peak, even though you use very little power from there.

Roff decided to put in 120kW, where our main usage lies. To give you an idea, in a typical week we generate about 119kW per hour from the sun, and our usage is around 116kW. So our system runs quite effectively.

Why are these ‘usage peaks’ important?

When you want to install a system, you have to decide how to handle these peaks. The most financially beneficial way would be to draw that power from the national grid, or the municipality. So you’d generate the bulk of your power and draw the rest for those high peaks from the grid, so you don’t end up with unused generation capacity that you can’t use or put back into the grid.

There is still a lot of technical challenges when it comes to selling power back to the grid, and the equipment is much more expensive for large systems, so take this into consideration.

Types of solar systems

There are two main types:

-

Hybrid system where you completely go off grid and have no Eskom power coming in, for example on a farm or in a private home. It’s a great alternative, because you generate all your power and the system runs on its own – it doesn’t need any reference point or back-up power. You simply connect solar panels to the hybrid inverter and batteries. You generate the power, and when you experience the peaks and your inverter is strong enough, it pulls the power from the batteries. The problem is that these systems are very expensive because the technology is advanced. It’s therefore better suited for home use, or for any moderately sized system. You can put power back into the grid, provided that the grid has power and the power utility allows it.

- Grid tie system – This system needs a reference point, since the system always needs to ‘see’ power. You can’t put power back into the grid. You have a reference point, which can either be the grid or a generator, to feed the peaks of your usage. In Roff’s case, we have 120kW solar that feeds our main usage. When we start a machine that generates a peak, it pulls power from the grid or our generator.

You’re looking at between six and eight years to regain your capital investment. The more expensive electricity becomes, the more entrepreneurs will use the opportunity to create alternatives and make money.

Fifteen years ago, South Africa had some of the cheapest electricity in the world which left basically no room to make any money. The current situation might just be conducive to entrepreneurial thinkers solving the problem for good.

REASON 2: Risk management

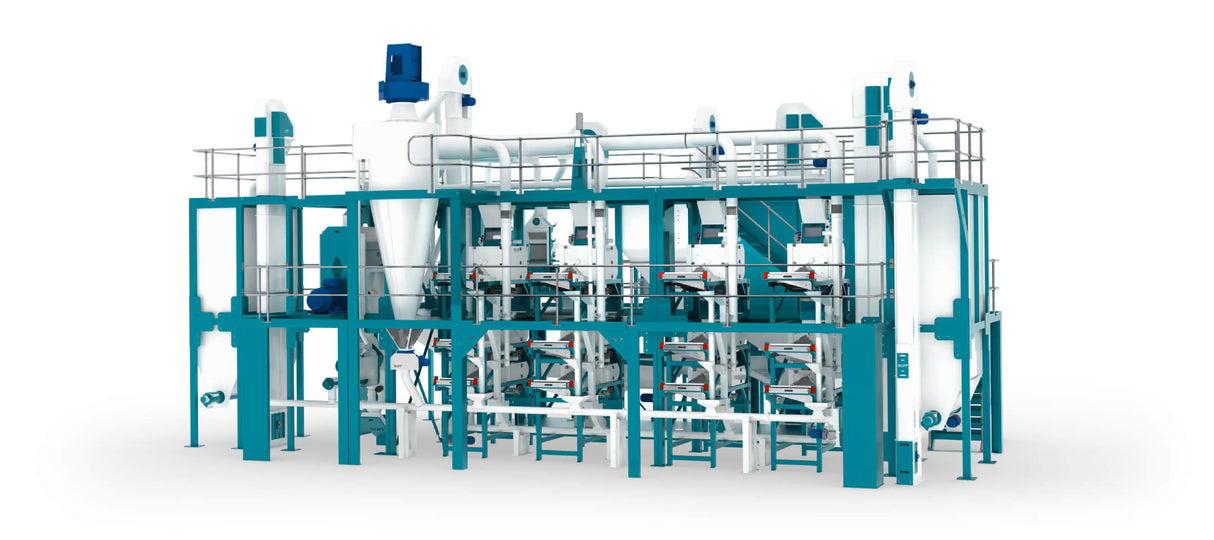

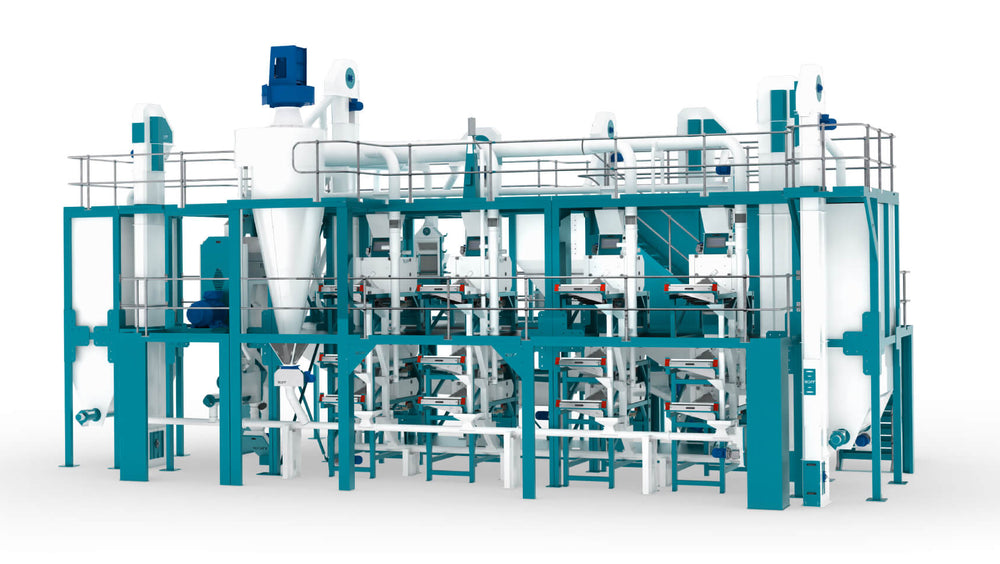

The second aspect of the decision to install solar at Roff was considering what the risk of being without electricity truly is for our business. This is a real cause for concern when you consider how much load shedding we’ve experienced of late in South Africa. It’s not only about having power and being able to work, but it’s also about working efficiently. In a production setting like Roff’s, our processes are already complex to ensure efficiency, but if we then have to switch off certain parts of the plant because there is no power, it results in catastrophic inefficiency.

One of the biggest risks for any business is when you’re at a place where you don’t make any profit. In South Africa, it’s already a challenge to turn a profit in our economic environment, following the COVID-19 pandemic, supply chain issues, etc. So the challenge for businesses and entrepreneurs is to get our businesses to a point where the impact of occurrences like load shedding affects us to a minimum.

From a business risk management perspective:

- We have a responsibility towards our employees or workers. We have to do business to survive so we can be here next year still. In order to achieve that, we have to be profitable. Roff employs 70 people, so if we don’t behave responsibly even if risk management measures cost us money, we run the real risk of losing profit, closing our doors and then 70 families no longer have an income.

- We have a responsibility towards our clients. We’ve been running the business for 31 years and we owe it to the clients who support us to behave responsibly and conservatively so that we can continue serving them.

We need to work to be profitable and have the capital to grow and manage our risks.

Roff’s tips for deciding on a solar provider

-

Don’t choose the cheapest supplier, choose a reputable supplier that uses proper equipment. Do your research, loads are available online. Your main elements are the inverter, batteries and panels. Read reviews to get a feel for the suppliers you may want to use. Stay away from the non-reputable ones. Even if it costs 20% more to use the best suppliers, you’re talking about a 20-year investment. Choose your partner wisely – one that offers warranties they can fulfil.

-

Software and reporting - If you can measure it, you can manage it. What software can the supplier offer so you can optimally use your system? Newer systems have an app so you can check the specifics online. E.g. your panels may get dust on them and then you can lose 20% of your power. If you’re aware of this, you can act in time.

-

The control system, especially if you integrate a generator into the system, is crucial. Plenty of industrial systems have failed due to the control system that has to integrate the solar system, the supply from the grid and a standby generator in times of loadshedding. This control system must manage the amount of power that is generated by the solar (PV) system, as well as whatever has to be filled in by the generator. It can become quite complicated when, for example, a cloud moves in between the sun and the PV system and the load has to be rebalanced between the PV system and the generator.

Roff initially considered seven companies. Two offered inferior equipment, so we decided against using them. From the remaining five, we dropped three because their IT reporting systems weren’t on par. We ended up choosing the supplier with the best reporting system.

In a nutshell: choose a good supplier with good products and reporting, as well as good installers.

Things to consider as a miller

Remember the following:

- In winter, your solar system only starts generating power from about 8h30 in the morning, and this starts declining from 15h00 in the afternoon.

- Panels: it peaks in the middle of the day. You have to design your system in such a way that you capitalise on this peak power generation.

- Daylight milling is still better than having no power and doing no milling at all.

Solar power is cost-effective and reliable, and the technology is becoming more and more familiar, with service providers on hand when you need advice and support.

It’s important not to invest in technology that’s too far ahead. Take for example the Citroën Pallas – a nifty little car with hydraulic suspension that had a host of features ahead of its time. Unfortunately, the supporting technology to provide owners with after-sales support didn’t exist in the 1960s to 1970s, so the car wasn’t as well received as one would have expected. Years later however, Years later, Citroën uses some of the same technology with great success, just because the component technology has been improved.

Roff’s solar system specifics

In its factory, Roff installed the following:

- 2 x Huawei Sun 2000 inverters that each produce 60kw of power

- 126 x Deep Blue 3.0 550W solar panels

Roff’s current power utilisation on its premises is between 150kW and 170kW which historically was drawn from the grid. Following the solar installation, 100kW up to 120kW of this demand will be generated by the system on sunny, cloudless days.

The system also enables Roff to run all its processes in the factory during load shedding, with the generator only carrying 40kW to 90kW of the load to serve as a reference.

The following solar equipment is being installed at Roff’s offices:

- 1 x 12kw Deye hybrid inverter

- 4 x SA Lithium 100Ah 5.1KW/h batteries

- 26 x 500W Mono Percium high grain solar panels

This office system will supply two server rooms, all security equipment, office lights as well as office plugs with power.

Roff looks forward to remaining productive during load shedding, avoiding downtime and managing this business risk effectively – by harnessing the power of the African sun!

Reference:

2 comments

Well done for going green. Thank you for sharing your solar experience.

———

Roff Milling replied:

Thank you

Hi,

I have a R40 ROFF Milling Machine in Kolwezi/DRC.

I would like to install a solar system for the plant.

Please can you recommand me to your supplier.

Thanks

Best Regards

———

Roff Milling replied:

Hi Jake, the sales team will get in touch with you shortly.